There are so many things that I would like to suggest to give you some food for thought. I’m sure I will forget some, but at least I can get them down in here.

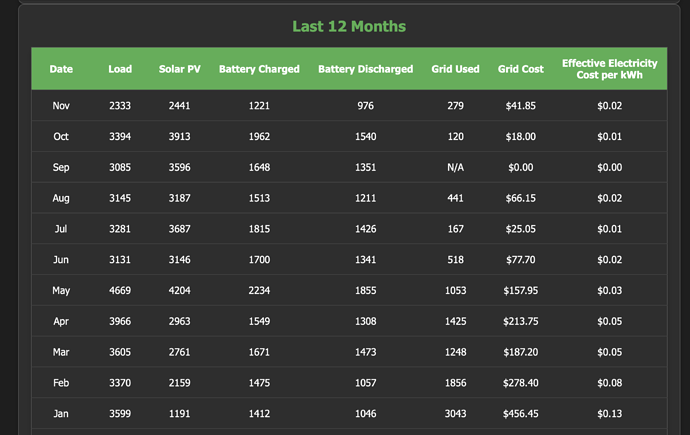

I’m in the PNW and our latitude is nearly identical to your area. I’ll give you advice based on my location and experience with my 45kw ground mount system.

I did the design, build, permitting, material acquisition, and install of my entire system. I would not really recommend doing this yourself, as you’ve suggested. It took a year from conception to activation and it was a lot of work. I would have made more $$ focusing on my business than I did installing it myself. With that said, I know just about everything there is to know about my system.

I have 96 panels in my system. Snow can be an issue and reduce production in the winter. I oriented my panels in portrait, 2 high. This way there is only one “seam” between the panels for snow to get hung up on. This will allow the snow to shed and melt faster. Most installers will install them landscape because it is easier and quicker. I am very glad I did it in portrait. The first year proved I was correct.

I used the Sunmodo racking system. It was very affordable compared to the other system and I’ve had no issues with it. I’m not a huge fan of the cast aluminum tops, but they worked out and I have not had any issues with them at all.

I ended up having to source my own panels as well as the local supplier (CED Greentech, you likely have one near you) fell through for the original panels that were selected. I ended up using BlueSun panels. I had been in contact with them for about 4-5 years prior. They are T1 panels. I wanted to go through a company for the panels for the pull for any warranty issues, but I was stuck between a rock and a hard place when the entire system was designed for a specific panel. It’s not very easy to switch panels. These were a good match and I had been in contact with bluesun for quite some time. I have not had any issues with the panels and CED even complimented on the quality of them. Ultimately, time will tell.

I would go with string inverters over micro inverters. You don’t see solar farms using micro inverters, do you? It’s because there is more to them with respect to install and also more to go wrong. Go stupid simple. String inverters are that. I always hear stories of people’s micro inverters failing. I went with Fronius as they were a great option and they have a large KW capacity for split phase. Mine are 15kw each. I have 3 units. They just came out with new ones as well and they can do battery backup. I have not had any issues with the inverters and they are cooled with a fan as opposed to just passive. Heat is a killer, I’m sure you know. Fronius is also a welding company, they are not new to building things that deal with power. They are also one of the top rated inverters in the world. I believe #1 in AUS.

I ran DC underground to my home, about 200-300 ft away, similar to yours. My DC voltage drop was about 1%. It was way cheaper to do this than convert at the panels and then run AC underground. Higher voltage travels more efficiently than lower voltage. Not only was it more efficient, but the wire was much cheaper and easier to pull this way.

I got my inverters and wire at “thepowerstore” online. They are located in TX and may have another location. Call and get pricing, it will be cheaper. I never purchased anything without “haggling”. It saved me a lot.

Get extra panels for your system so you can have a few spares of the exact same panel. This way if one gets broken/damage or fails for some reason you can simply swap one in. I have about 7 spares. I had some damaged in shipping too so I’m glad I got extras.

If you don’t have the inverters “attached to your residence” then you can do a maximum of 1kv on the DC side. You can get around this by simply putting them on a freestanding rack with unistrut etc… similar to how you have your power setup at some of your miner locations. The 1kv will be more efficient for a few reasons. You will have less “strings” and you’ll save more in transmission as well. I decided to not do any parallel combiners. Each “string” goes to it’s own MPPT on an inverter. Again, keeping things stupid simple. I oversized my PV wires for the home run by 2awg so I have room to upgrade panels/production in the future. It also decreases voltage drop and the cost was minimal.

I would only consider bifacial panels. It’s a minimal cost and you’ll generate more power and shed snow quicker in the winter. They will produce a small amount of power even when completely covered in snow. This will allow them to heat up and melt snow more quickly. It will also get your inverters to turn on more quickly in the morning. These are all minimal things, but still.

I went with the highest engineered stamp on the sunmodo racking. Most system are about 35 degrees for pre-engineered/stamped. I did this because the higher degree will allow better snow shed. I also mounted to system as high as the system design specified because you will get snow shed off the panels. It will pile up and you don’t want to be out there clearing it all the time. We don’t get a ton of snow, but we def get some so this can be an issue in snowier years.

If I were to do it again I would consider:

Heterojunction shingled bifacial panels. There’s a slight efficiency bump and the layout of the individual cells is top to bottom instead of side to side when in portrait. This combined with portrait install will allow faster snow shed as the top of the panels will be exposed first and generate power that way.

My panels are 465W. I would def go with larger panels vs smaller 400 or sub. I think around 450 or so it decent. Make sure you have glass on the front and back. You can go larger, but my feeling is you could get issues over time with them sagging/breaking.

I would consider a single axis tracking system. I don’t know the cost, but I would look into it. You can gain a LOT of production with just a single axis tracking system.

I would take more consideration in creating a an array that looks like this:

\_/

That’s the best I can do with keyboard characters. The underscore would be facing directly south and be roughly 50% of the array and then making the other ones southwest and south east. This also allows you to utilize the space inside the array as opposed to creating two arrays like this =

You will get a better power curve through the day, which if your power company changes the rules you will be thankful for. If you have use batts you will also be thankful for it. You may even slightly generate more power.

Another consideration is bifacial panels in a vertical orientation, like a fence. There are studies showing that these are actually outperforming traditional array configurations. I believe this is due to temperatures. The vertical panels don’t trap the temperature. The efficiency goes way down in hot weather.

Extras,

I ran 120v power out to my arrays for tools or whatever you may need

I also ran an ethernet line

I added water out there too

I laid down a stabilization layer on the ground (geofabric, stuff they use for roads) and then put a light color rock on it. I did this to keep it clean and the light rock has a better albedo for reflectivity to help the bifacial panels. I’ve very glad I did this because I don’t have to mow around the panels. I walk through a few times a summer and pull the weeds, which are very easy to pull with the geofabric there.

I don’t wash my panels, I let the rain clean them. Be careful of hard water. Don’t let sprinkler water hit them or even mist them.

Use these two sites:

https://pvwatts.nrel.gov/ (insanely accurate, IMO)

https://www.suncalc.org/ (insanely useful for viewing the sun positioning)

I am sure I forgot stuff, but let me know if you have Qs. Feel free to DM or get in touch on discord/telegram. My PV system has been functional with miners running for over 2yrs.