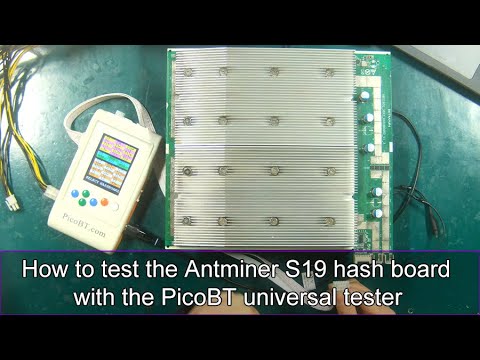

This thread I will update and document my own repairs to demonstrate it can be a good investment. I haven’t completed all of the theory test yet, I just need to make a video explaining how the hash boards of the S19 miners work before moving onto the next stage of the course.

All the equipment plus course cost $1600 usd.

The first thing I did with this equipment was a gentleman on this forum posted about turning the S19 90th J1-11 model into a 104th S19 J pro. I realised I had the equipment to do this, and bought one for $900 when the market price was about $1200 for a J pro, which runs well at 104TH and runs at 117TH for about 3800 watts. So I saved $300 there.

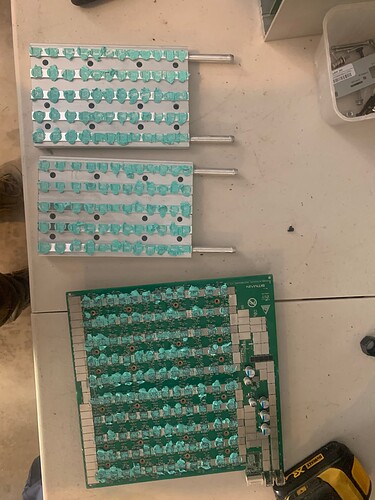

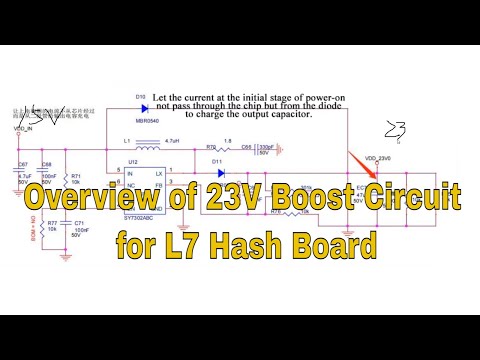

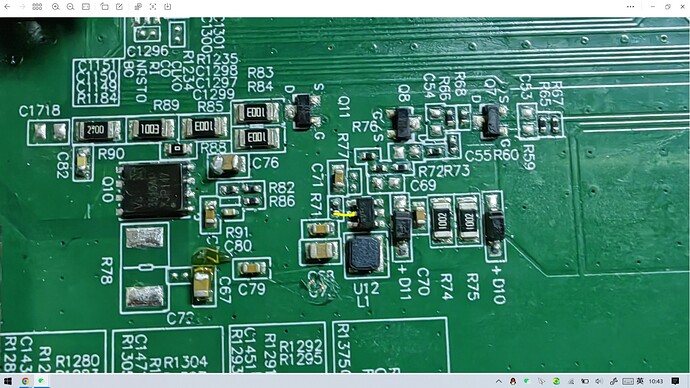

The other day a board on my L7 went down. The kernel log said it could only find 73/120 chips so I’m assuming the break on the chain is the 74th chip. Unfortunately my picobt is not updated and does not have the L7 board tester installed, so I’ve ordered the correct usb so I can plug it into my computer and update it, which will come next week. However in the mean time I took the water cooling plates off my L7 and found this

The thermal paste I’m pretty sure should not be bluey green, and I think that means I’ve got moisture in my miner. Because it is a water cooled miner, I have one side of my miner blocked off with the stock fans on the other side to take the heat out, and I have one side blocked off just to keep it clean. This is probably the issue having one side blocked off.

So I thought I’d replace the thermal grease and see if that will fix my issue while waiting for the usb so I can properly test my hashboard, unfortunately it is still giving an error on the 74th chip.

So I am ordering the BM1489 chip that my L7 uses, each chip costs $25 and the MOQ is 10. So that’s a $250 cost, however it’s important to note:

- My L7 is out of warranty

-there’s no local repairs and shipping each way is $200, as well as I think each board diagnostic plus repair is $100 from memory

-I should only have to wait 7-10 days before I can fix it. Next time I should have no waiting time compared to a month wait at best sending it to the US or Asia

-I am still running the miner with only 2/3 boards

So really this one repair alone is saving me $250, but can cover other repairs in future. If I get my shit together and finish the S19 course I could do the L7 course and offer local repairs to other L7 miners and make money back on the spare chips like that.

One thing I’ve learned just from this one time changing thermal paste is how it can spread over unwanted parts. I’m going to design and 3D print a cover that screws into the board while I’m cleaning the thermal paste that only leaves the chips showing but covers everything else so I can clean it easier. Each model I’d have to 3D print a different design, example L7 has 120 chips while J pro has 126 chips.

So at the moment I’ve saved $550/$1600 from this, and it has been fun learning and I’d recommend it if you’re in for the long haul