Hello,

Trying to come up with a solution to get rid of heat in proper way.

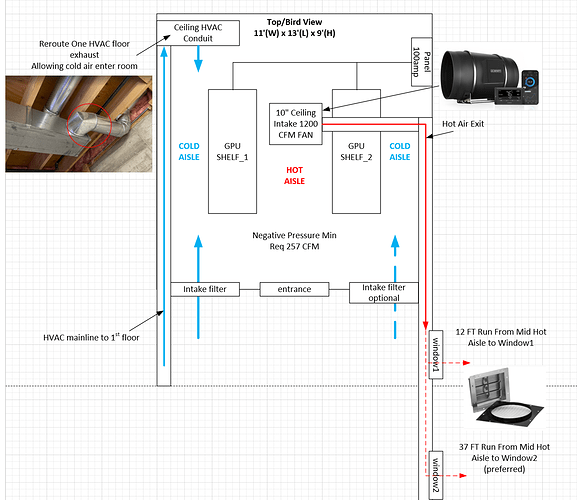

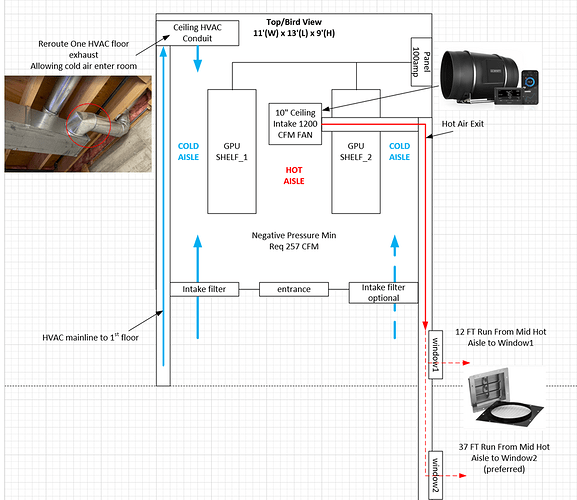

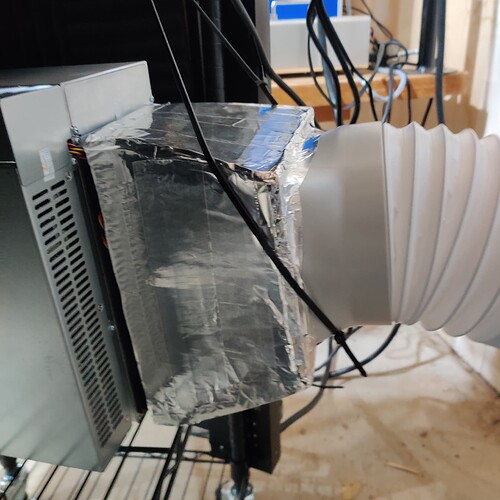

Diagram below represents proposed design. HOT aisle will be in the middle of the room with 10" (inch) intake fan (1200CFM) removing excess heat.

According to omnitecdesign room by 11’x13’x9’ requires 257 CFM for negative pressure. That being said I’m hoping that 1200CFM intake should be enough to do the job.

I have two questions that I would love to get assistance with:

1)I have ability to reroute one of the HVAC conduits to the mining room and bring cold air. Questions around that. Since this is cold air do I have to run ducking all the way to the floor or let the cold air settle by itself? Additionally, Is there any potential harm for hardware equipment by introduction AC air?

2)There are two exhaust windows as an option. One is located 12 FT from the HOT Aisle and second one 37 FT. 2nd window being preferred I wanted to ask if the exhaust distance will have an effect on the performance of the intake fan?

Thank you in advance. Any feedback is greatly appreciated!