I’ve had a little time to check some more things out. The subflow is simply pumped into this lower chamber below the flow plate. In my opinion, with sufficient flow there is nothing wrong with this. They have sealed the flow plate to actually make this “chamber” which is really good to see. This makes sure the flow actually goes through the miners and no other way. There were quite a few screws to get to the point to get these shots. The magic will be if this chamber ends up being slightly pressurized. This will ensure even flow to all locations. The OTHER thing I REALLY like here is the flow comes down the middle and the miners are all on the outer part of this chamber. If you guys recall, I actually had negative flow in the asicshield right in front of the inlet. This will not be an issue here because there is not a miner in this spot. That is where the return trough is.

I have also taken this a step further and done some basic calculations.

1.5mm circle area = 1.767 mm squared

396 * 1.767 = 699.732

66 x 6 = 396 (total amount of holes for flow between all 6 miners)

1" = 25.4mm = 506.71 mm squared (area of 1" inlet)

22GPM/6 = 3.67GPM / Miner (This is the estimated flow per miner). This is on par with what I’ve gotten from those running large scale. Given this accuracy, we should be good here as well.

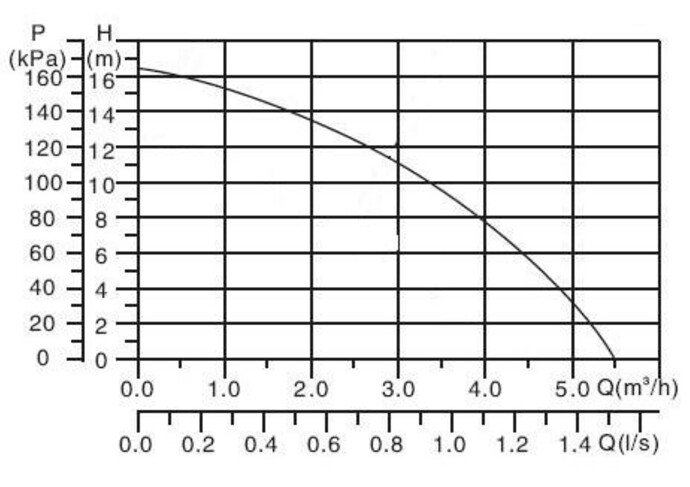

1.4 L/s is roughly 22GPM. It may be a little lower due to some losses and a slight pressure. Even hat about 35kPa (about 5psi) we are at 1.4 l/s. I think this number would be decently accurate.

While there is more area when combining all the small flow holes than there is via a 1" inlet, it may end up actually being very close in flow due to larger resistance through smaller holes. Once I get some fluid in this thing then I’ll go ahead and do my “flow check” at all the locations. I don’t have a way to really measure the pressure, but this will give a good indication.

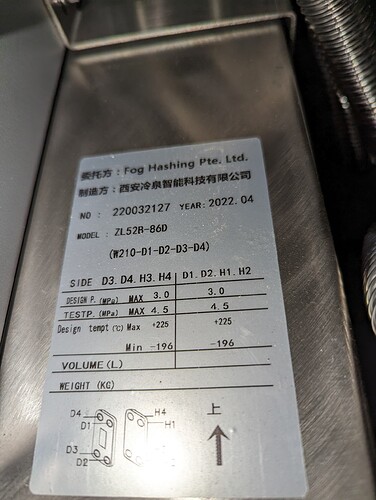

The metal tubes that were utilized between the heat exchanger, pump, and tank was a good choice.

At this juncture the only things I can see that could be improved would be putting a drain for the oil and a shutoff valve at the inlet and outlet of the tank. These are minimal and not necessary, but would make maintenance much easier if something need replaced or repaired.

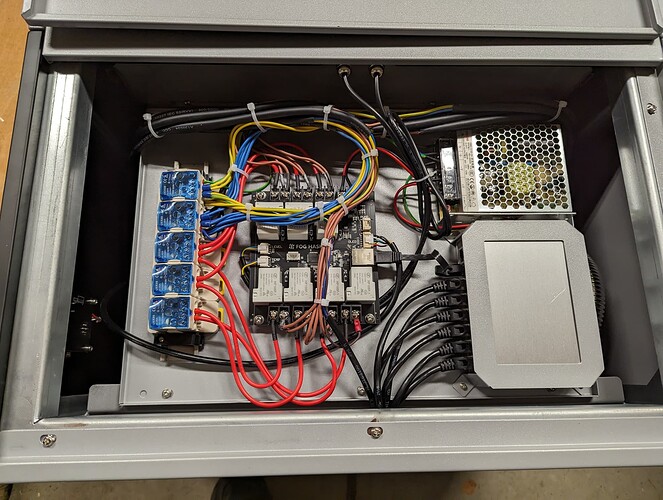

The cabling is done well and encased/sheathed where it needs to be. My only recommendation here would be something to discourage chaffing where the cables come into the tank where they plug into the miners.

These are both very minimal things.