I should be able to provide a pretty big update on everything next weekend. I’m just waiting to finish up a couple things.

It was 30-37F today outside and I’m dumping heat in my garage trying to get rid of it. The house is definitely WARM and my 800sqft office is WARM as well. I have some automation setup to dump heat in the house and office first and then the garage last if oil temps are still rising. The house hvac fan does run 24/7. I have not tried to control my nest thermostat yet via any automation.

I’m not too sure this will all be the way I control the fans in the end, but it is something I could implement quickly. The thing I don’t like about it is there is a dependency on the server and software to be up. If that goes down, for whatever reason, then I’d only be left with the hvac system running which isn’t enough to cool the oil in these temps. I will be moving a large UPS to the server room (need about $500 in wire) and I may put these services on a dedicated dell r630 that I have that will reboot and start these services automatically upon power coming back online. I would say maybe 15F and above the hvac alone would not be enough. For now, it’ll get the job done though.

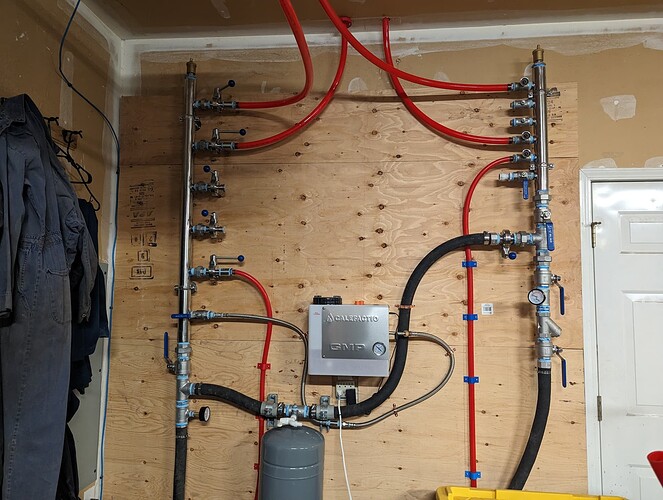

Not a whole lot happening. Here is an updated pic of the reclamation distribution and return system. I just installed the white tank in the middle. It is an automatic makeup system for the glycol side. If there is a small drip/leak it will keep the pressure in the system to whatever I have it set at. For whatever reason, I thought the output was on the other side, which would have been way better for a “clean install”.

Below is my current dashboard I’m using as well. I added in a circuit monitor to monitor the miner power consumption.

1 Like

The system is working awesome. I love it and there isn’t anything much better than saying your house, and other spaces, are solely heated by bitcoin mining machines. The best part is you can’t hear them

The next part of the project will be to automate the dry cooler. I have already broken out both fans on the dry cooler, but I want to create a circuit and way to automate the fans based on the temp readings I have for everything. This way when I still need a little heat for the house but it is 45-50 and above then it’ll automatically kick one of the dry cooler fans on to maintain immersion oil temp because the heat reclamation won’t be able to keep up with heat dissipation at about the 50F ambient temp mark. All fluid flows through the dry cooler anyways, so it is easy as turning the fans on or off. Again, I wish the dry cooler fans had a high/low as well. I’ll probably look for some when these burn out. Actually, I should find some before that happens so I’m ready with replacement. ha

I probably won’t get to heating hot water or the hot tub too soon. I’ve got to focus on my business, which actually pays the bills. ha. Probably later in the summer, depending how much work I can accomplish. I will update my schematic for the system and get it uploaded though!

2 Likes

@HBIM_Channel Quite a bit of new info since you were last here, at least that I know of  BTW, great videos on youtube. Anyone looking to start building a reclamation system, I would highly recommend checking out the channel. I’d actually probably say it is mandatory.

BTW, great videos on youtube. Anyone looking to start building a reclamation system, I would highly recommend checking out the channel. I’d actually probably say it is mandatory.

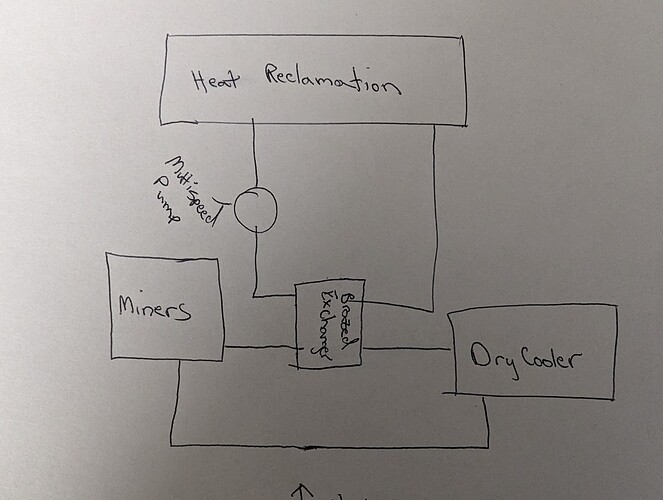

I was thinking about the configuration of the system and heat reclamation. Most heat reclamation systems in climates that have seasons will not need 100% of the reclamation. This leaves a lot of wasted power on the table with the current design IMO. If changing the oil configuration to simply go through a dry cooler instead of the glycol/water mix going through the drycooler then in the months where you only need some of the reclamation you can simply kill the water pump or run it at a much lower speed. My water pump draws 5-6A at 240v. That’s quite a bit of power. This would also make the drycooler more effective at cooling the miners.

A sketch to the configuration I’m referring to. @HBIM_Channel What do you think??

edit: apparently i can’t take photos and the arrow at the bottom is cut off. The bottom loop is immersion fluid only.

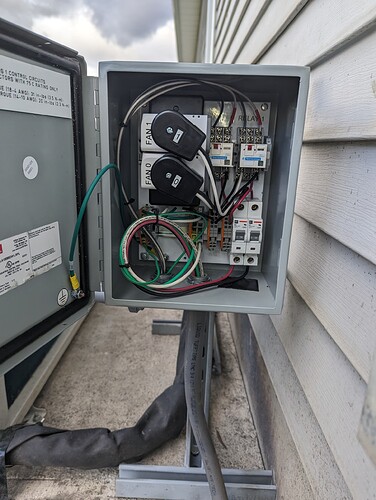

I’ve been working on an automated control system for the drycooler fans. They are on/off single speed fans that run off 240v split phase. I’ve been utilizing sonoff s31 wifi plugs to control my hydronic fans. I’ve used these plugs for many years on other projects and they have always performed flawlessly, so I have a bit of confidence in them. They are flashed with tasmota firmware. I decided to go this route because not everything that needs sensors is in a central location. I am collecting data throughout multiple physical locations on the property. All of the data goes into databases and I can write code/rules based on whatever parameters I like. This is why I’ve chosen to control things this way instead of using a PLC or hardware set rules. This allows me to adjust things on the fly to tweak the system for best performance as I learn how it performs in difference seasons.

This backing plate with components is just sitting in the box now. I need to find a way to mount it near the drycooler and then I’ll need the run the necessary wiring to it and the drycooler. It shouldn’t be too bad.

Basically, the wifi plugs are 120v units and they control two other relays (one for each drycooler fan). Those relays have a 120v coil and I can pass the 240v split phase through the relays. I have a couple 7A single pole breakers in there. That SHOULD be enough. It’s all they had at the place I get most of my electrical from. If it isn’t then I’ll be ordering up some different ones. The fans together only draw about 2-3A, so a bit more on startup. Fingers crossed. I wanted 10A, but no luck.

One of the things I implemented on the “wifi plugs” is that they will turn ON automatically IF the grid goes down and comes back online. This is controlled within the actual wifi plug without any additional services. A power outage could potentially leave my server and relevant services that control the system down, so there would be nothing to control the fans and the miners would overheat since the miners will run as soon as power is back online. This way all fans will turn on no matter what with a power restoration to ensure the cooling of the miners.

1 Like

The control system is in place now! I believe the wifi modules are connecting well through the metal box. It was definitely a concern of mine and really time will tell on that one.

I really should probably have the two DIN mount breakers tied together and I probably will get a new breaker next time I’m at the salvage center if they have one. I also made a stupid mistake when getting the #14 wire that goes to the dry cooler from the control box. I wanted red, black, and green. I actually wrote it down that way and somehow I had the guy grab black, white and green. For the sake of getting it done I just taped the ends red, which is just fine. It just bothers me more than anything. ha.

On a kind of bad note, the miners are currently down as of last night. When doing the electrical to the control box from the breaker panel, I noticed that my other panel was extremely hot. This is the panel the miners are running off of. After extensive troubleshooting, I have deduced that it has to be a failing main 200A breaker. I am headed to pick one up this morning and I should have it installed this evening. Fingers crossed that fixes the issue since I could not find anything indicative of another issue (arcing elsewhere in the panel). Pisses me off I have to have the miners down and I had to turn the furnace on. haha.

Edit: isn’t mining supposed to be “passive”?  for all those that think miners don’t do any work except turn machines on and sit back.

for all those that think miners don’t do any work except turn machines on and sit back.

1 Like

Main breaker replaced and we are back up and running! It was definitely scorched on the contacts for the stab connectors. With confidence, I can say that was definitely the issue.

1 Like

I just got the electric bill for last month, which was the first full month of reclamation. My estimation is that the reclamation system saved over $200 on that bill. It’s hard to get more accurate than that, but I do know it is $200+. I do expect after next winter season it will be paid for since there isn’t much reclamation in the summer months and I don’t anticipate having hot water reclamation this year due to needing to focus on other things. The return on the hot water would be a bit longer as well.

I was hoping to have more of the current cold season on the reclamation system, but waiting for parts really slowed that down.

Edit: It’s actually probably more like $250 since I heat my outbuilding with pellets and no longer have to. Not to mention it is all automated now and everything is WARMER. It’s a massive success and win in my books.

2 Likes

We have hit the season here where I have way too much heat and I need the dry cooler. I wanted to run a test to show the most efficient oil temperature range to operate the S19XP units. I have found that a range of 32-37C is optimal, with up to 900W overall savings over the oil temps being around 45C. I saw a drop of the system (without fans or water pump). This will now be my target range when I don’t need the water that hot to heat my home and at night time in the summer when the temperatures cool down to where I can actually cool it down that much. Below the optimal temperature range they begin to use more power. I think this may be due to trying to create more heat to get to their desired temps. This is just a guess on why they use more power.

i’m finding my miners like around 30 C before I had the dry cooler turn on for efficiency

Which miners do you have?

Ya’ll ready for the halving!?

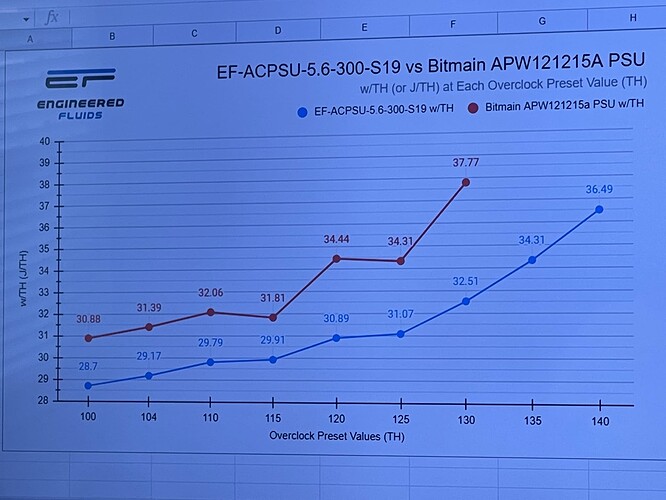

You can change your bitmain power supply out to aftermarket to get better efficiency.

Interesting. Do you mind me asking how much the PSU was?

The S21 Pro… specs look amazing. I’m very surprised they’ve been able to make that large of a jump in efficiency. It’s half tempting to try and get a couple for next winter.

The number are for s19. I believe i got them for $329 6500w.

Tuesday i have a s21 with a epic control board coming. I should have the number by the end of the week immersed.

I was wondering if the eipc boards would work with the s21 units. Please do keep us all posted. I loaded the braiins fw on one of my s19xp units and the bosminer kept freezing, missing data, etc… it didn’t like something about my miner. I provided them logs and data and they just said my miner was broke. They were responsive, so I will give them that. The miner hashes fine on stock fw though.

Ok I got some numbers before I popped the transformer at the pole. The electric company keeps putting up a small transformer you would think the thrift time they would smarten up. S19 xp with epic board. I put an 6500w power supply. Chips set at 175t. Holds around 178t with 3900w draw. 22j. S21 with stock power supply 238t. With 3800w draw. 16.8j to 17j both are immersed in bit coolant.

S21 also had an epic board. But the power supply can’t handle over 4300w.

that’s awesome. Have you tried other firmwares? What made you settle on the epic boards?

Was using braiins but i need to get the dev fee out of my business