I don’t blame ya. I’m currently using braiins pool, so that’s why I thought I would give it a shot since the fee is removed when you use their pool.

The latest dash for monitoring the system. Not a whole lot has changed, but minor tweaks.

Right now the dry cooler is so over powered, even with 1 fan, that I see the fluctuations frequently between about 33-37C. That’s why you can see the sorta zigzag patterns in the output oil temp and it directly correlates with the power consumption chart too. All very interesting data for sure. She’s been steady as a rock. It does seem that possibly I could have slightly more errors at the cooler temps for whatever reason, but definitely within where they have been operating since basically day 1. They’ve been running almost 15 months now and almost a year in immersion. It almost feels like I’ve found a cheat code with the reclamation and solar.

Mostly thinking aloud here, but it may not actually be worth it to heat residential water with the miners due to the higher miner/oil temp needed. This would reduce the efficiency of the miner to a point where it may be near a wash, electrically speaking. Obvious this would be different if you were heating a pool that requires lower temps and will be more of a constant heat transfer as opposed to 60-100 gallons in a storage tank.

I’m going to run some numbers and I’ll let ya’ll know what I come up with.

If im reading it right, you dont think you will be able to heat a hot water tank because you wont be able to generate enough heat at the miners current efficiency? What if you had a insulated hot water tank hooked up and you overclocked your miners when you have solar running to get the additional heat without drawing too much power from the grid?

Just a thought: Would Running a recirculation line between your water heater (or super stor) inlet and outlet short cycling the water (until need for hot water) create enough of a heat transfer from your miners to be effective?

Are you hitting a heat transfer plateau?

It’s a matter of how hot do you want to heat your pre-hot water tank (storage tank) vs what you would save in electricity by not doing that and the installation and infrastructure costs. A pool would probably be the PERFECT candidate because you could very easily heat a pool to 70-80F and only need 90-100F oil at the absolute most. Each heat exchanger you go through you will lose x amount of transfer. If my oil is 100F then my water glycol ends up being around 90F. The only way to close this gap is to slow down the flow, but if I do that then I believe I will reduce my cooling capacity for the miners. Some nice multispeed pumps would be amazing to test this.

The thing here is, the hotter the miners run the more power they use. I’m running them right now with the oil temps at about 33-37C. This saves about 600W of power. I’ve dropped from 12kw to 11.4. That equates to about $43 a month at an electric rate of $0.10 USD. Once I get a circuit monitoring setup for my my panels then I can monitor my electric usage on the hot water tanks, but I doubt it is substantially higher than that. And the storage tank only supplements the hot water tanks. The hot water tanks will still need to heat the water a little and then maintain those temps.

Hot water is typically around 140F in your tank. I think heating a large storage tank to about 100F would help a lot. In order to do that the miner oil would need to run at about 115F (46-47C). In the colder parts of winter the tank will be that hot to provide more heat and the in hot parts of summer July and August it will most certainly be at that point because the dry cooler doesn’t cool them more during the day.

So the concern here is, is the investment, time, infrastructure and space needed worth it for this? My initial thoughts now are it is not. If you have a pool then absolutely because the water doesn’t need to be “hot”. Same goes for if you have a hot tub. You would want to maintain a hot tub water temp of 101-102 (more or less depending on preference). I suppose the more water you have to heat then the more plausible it becomes.

It’s just a matter of efficiency of miners at a certain temp vs gains from heating water plus costs to do this. Even if I did all the work myself, I would recon it would still run me around $2k to implement this with a 60-100 gallon storage tank. I’m sure it would prob take me roughly a month to do this as well as I would need to change the plumbing in the house to be adaptive to this setup.

Be careful when messing with your water heater. If your machines for example don’t get the water hot enough, bacteria can grow in there and make you sick. I’m just saying because it’s happened to me

I am aware of this as well and something I would address. Everything would also go into a traditional hot water heater after the storage tank. Thank you for the heads up though!

Use bigger water tank with two spirals inside. Pump heat from miners into lower spiral and use hotter heater on your top spiral in that tank (water tank acts as heat exchanger).

This is how it works for 6 years already in my house. Place where I have installed our first, proof of concept product. Still operational after all this time! Sime miner, same liquid!

FITCool6 - FlameIT - Immersion Cooling Liquid

In my house I run cooling liquid through two water tanks. First “Hot one” later “Cold one”.

You can read some more about it here: https://flameit.io/assets/pdf/articles/onet-noizz-mines-cryptocurrency-and-heats-house.pdf

@live4soccer7 happy to read Your thread. Well done with Your project. I am bit sad, though, that You haven’t bought anything from us ![]()

Anyway, keep the great work!

Have You managed to solve Your hash stability issues? I don’t know exactly, maybe I’ve missed but have You done anything with TIM (Thermal Interface Material) between chips and radiators?

Paweł, CEO of FlameIT - Immersion Cooling

Great to hear from you, Pawel! It has been a journey, to say the least. It is quite successful though after a lot of work.

I will be revamping my system at some point and I’m sure I can find some items to buy from you ![]()

Are you suggesting to put a circulation pump from the electric hot water tanks in the house to the top coil on the buffer/storage tank and have the miners hooked up to the bottom coil?

My reclamation system is very “rudimentary” at this juncture as I needed to get it up and operation for the winter and I also wanted to be sure it would work before expending more money on it.

edit: I do have two 134 XP units that hash at around 132TH compared to the 135TH when they were running in air for a few months. I have not figured out why yet. It happened as soon as they were immersed. I have moved them to different positions in the tank etc… but the result is still the same. I have not tried any “TIM”. Do you have a specific product you recommend for this? I do not know if this is a power supply issue or chip issue.

edit: one thing to note is that if I cool the oil enough (around 20-25C outlet) then they will begin to hash again at a full 135TH. That doesn’t happen to often and now that I have more granular control over the cooling they probably won’t see those lower temps since they seem to use MORE power at those lower temps (basically below about 32-33C outlet oil temps).

I just had an idea! I am on a well and the water comes out of the ground quite cold. I also have a large lawn that requires a ridiculous amount of water, ugh… I’m not a huge fan of having excessive lawn and I’m trying to downsize it, but it is what it is for now. I have to water for 6-8 hours a day during the summer months (june-sept).

WHAT IF I created a glycol loop that exchanged through the a brazed plate exchanger with the cold water before it waters the lawn and that glycol ran through the heat exchanger in the furnace, effectively giving me “Air conditioning” during this time of watering. THEN after the cool glycol goes through the water to air exchanger it could head back to the miners providing cooling there. 1/3 to 1/4 of the day could provide a great amount of cooling to the house and miners with a system like this.

Note that I haven’t even begun to think of the layout or best way to go about it. It is literally something I thought of a few minutes before this post!

just curious i understand you have two system , which one you are running right now ,where you getting the data from ? thanks

I have just one system and I log and collect all data internally on private servers/databases.

i remember you had another thread with a different system from Asicshield , before you started this one with Fog hashing , but within this thread i saw you posted a picture of Fog hashing system not installed , and you were sharing some numbers already , that why i asked from which system were you getting all this data , was it running Asicshield system or the one from Fog hashing , Cheers

I’m going to create a post with a summary essentially to condense information and also an explanation.

I have used the B6D and my unit in conjunction. This is due to the electrical being ran for one and also different heat heat exchanger fitting sizes, specifically for the water side. It was the quickest to put them side by side and do it this way to minimize downtime before the halving. At some juncture I will get the C6 or the current version of the 6 miner unit they have available at that time.

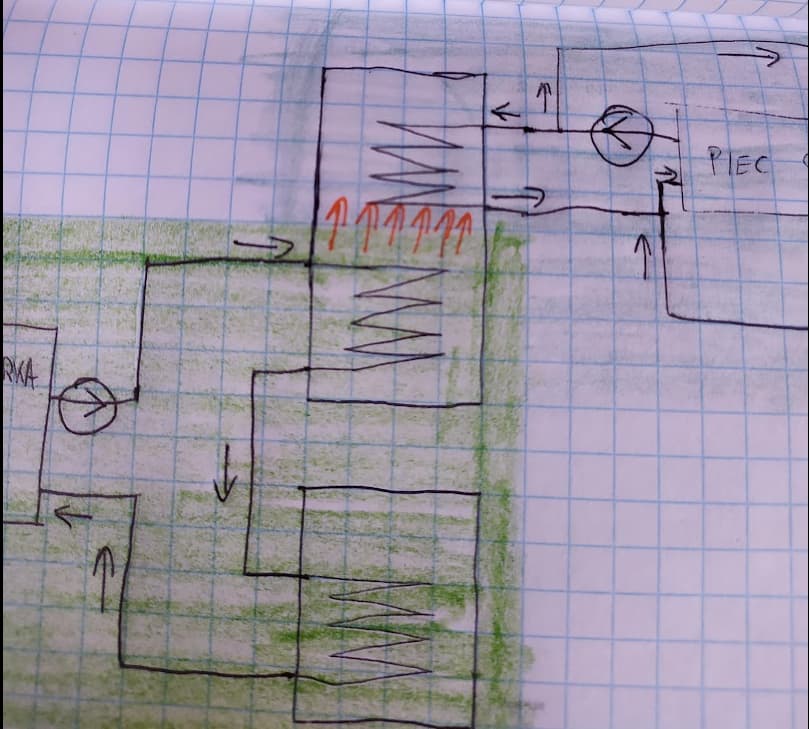

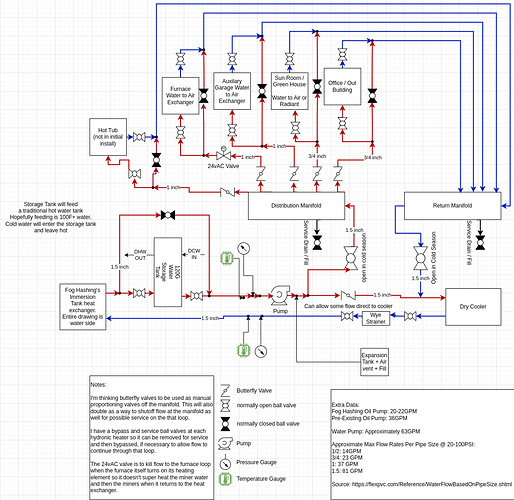

Disclaimer: I am by no means an experienced designer in hydronic systems. If you use any of this information then please use it at your own risk. This is also an evolving system that I will make changes to over the years. I have implemented some of what is in the drawing, but not everything yet.

The general setup is to take the hot oil from the miners and run it through a heat exchanger. The other side of the heat exchanger has a water glycol mix. This is what is utilized to heat different things in the system (house, garage, etc…).

Why use glycol?

This is to help the water from freezing in the event that the miners are not running in the winter for whatever reason. Most glycol mixtures also have corrosion inhibitors. This keeps everything clean and working efficiently.

Ethylene or Propylene Glycol?

I am using propylene because if there is a break in one of the exchangers that is being used for water in the house then the propylene will not kill you. I am using about a 30% mix. I didn’t see any need to go higher and I believe 30% is usually the minimum. If there is some sort of catastrophic failure and it is very cold outside then I would drain that part if I thought freezing would be an issue. The higher percentage of glycol in your mix the worse your heat transfer will become.

What am I currently heating with my system?

My entire home (about 2600sqft), my workshop/detached garage, and excess heat is dumped into my garage where my vehicles are. I use the garage space as a flex zone so I can control the temperature of the miners better in order to suite my heating needs in the other more important spaces (home and workshop).

How many miners am I running?

I am only using 4 miners in the 6 unit tank. My objective with this project is to utilize my extra solar power and to not excessively exceed my heating needs. Also, by having extra space in the tank it will allow me a little flexibility if I get a new miner, want to sell one, or if one is down I can just throw another one in the tank, etc…

How do I control everything in the system?

In a shell, I utilize esp8266/32 units for temperature readings in the oil for input/output temps. I also utilize the same devices for air temperature in the house and other places I want to monitor. They all report back through MQTT where I can then use this data to create rules/flows/programs. This is done in node-red. All of the data is also recorded in influxdb and can be viewed in either home assistant or grafana for analysis. I control the drycooler and the two hanging hydronic heaters with sonoff plugs. These work in a similar way as the esp units. I can control them via node-red flows. The last controlling point is the thermostat in the house. I am utilizing the latest generation ecobee premium and I am using the homeassistant integration for the thermostat. With this I can utilize node-red to create rules for the thermostat fan. This is quite simplified, but the gist of it is there.

What heat exchangers did I use?

On the mining system I am using a brazed plate heat exchanger. I had to use one I previously had due to the size of my water pump that I already had.

I used water to air heat exchangers on the glycol side. The hanging hydronic heaters are these: https://www.freeheat4u.com/100k-hot-water-hanging-heater-unit-heater-WATER-TO-AIR-HEAT-EXCHANGER-100000-BTU-AIR-HANDLER-2-speed-blower-fan-with-remote-thermostat-and-onoffon-switch_p_382.html

I went with the above ones, specially, because they are a 2 speed fan. You’ll see different variations of the same heater online. I wanted the 2 speed fan to keep the noise down, but to also have the option to increase heat output if needed. THere are some variable speed setups, but those fans are not designed for that and will likely fail early. I can also easily control the two speed fans as well.

I oversized them simply because I knew the water temp would be a lot lower than what you would typically get with a boiler system.

The exchager type I used for the furnace is this: https://www.freeheat4u.com/Water-to-Air-Heat-Exchanger--Import_c_37.html

So far I am very pleased with the heat exchangers and I have had zero issues with them.

What is the general flow of the system?

Oil: Miner Tank → pump → brazed plate heat exchanger → back into the Miner Tank

Glycol Side: Heat Exchanger → pump → heat reclamation distribution → cold water side of the reclamation system → to the drycooler → heat exchanger

Design Considerations:

I wanted to keep this as simple as possible, especially for the first iteration. This is why you don’t see mixing valves, diverters, etc…

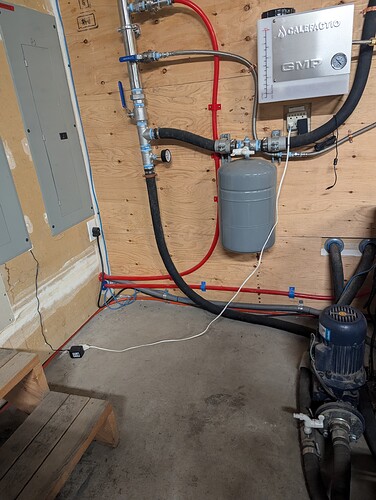

An expansion tank should definitely be in your design to allow for the fluid to expand as it heats up. I will downsize this tank on my next iteration of the system.

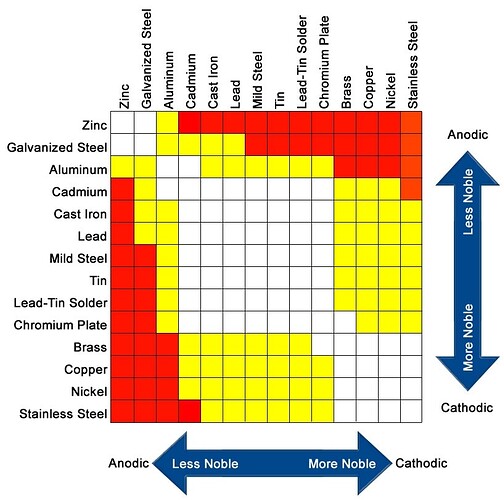

Glavanic Reaction/Corrosion - I took this pretty seriously. If you put metals together that have different electrode potentials. This can cause all sorts of issues. I kept pretty much everything stainless steel. You can go very far down this rabit hole, but I feel as though I did a decent job in this aspect on the project.

I utilized butterfly valves on the hot side of the distribution system so that I could manually adjust flow to heat heat exchanger. I was unsure of how well the system would function and this allowed me very easy adjustments. I ended up making one adjustment at the beginning and never changed it again until the summertime.

I added in a bypass system so that I don’t have to push all the fluid through the heat reclamation system. This could increase flow rate and increase cooling abilities, but more importantly it will allow the miners to continue to run while I work on the heat reclamation system.

I also wanted an automatic glycol makeup system so that it will maintain the pressure in the system. It is very difficult to not have a minor drip here or there on npt fittings. In all I’ve probably only lost a couple tablespoons of water/glycol through npt fittings. Nothing to worry about. The makeup system all helps me recover from minor issues as well. It was well worth the money.

How has the system performed?

Last winter was the first year I was able to use it. It worked amazing. It kept my family and I warm all winter. It provided enough heat to keep us warm until about 15F outside. If it was colder than that then I simply ran our pellet stove in the house to provide a little supplemental heat. I never ran the heat in the traditional hvac system once I activated the reclamation.

I have attached some photos. Here is the overall design that closely represents my system. Again, I have not implemented all of this yet, but you get the idea.

Hanging Hydronic Heater brackets/holders:

Glycol water pump and automatic glycol makeup system:

Hanging Hydronic Heater in the garage:

Hanging Hydronic Heater in the workshop:

Ditch to the workshop:

Heat exchanger placed on the output of the furnace air handler. While it may not be the absolute ideal place to put, this is what I eneded up doing based on the existing system there. The arrow does no indicate airflow direction.

Foghashing unit after “unboxing”

Drycooler and hoses:

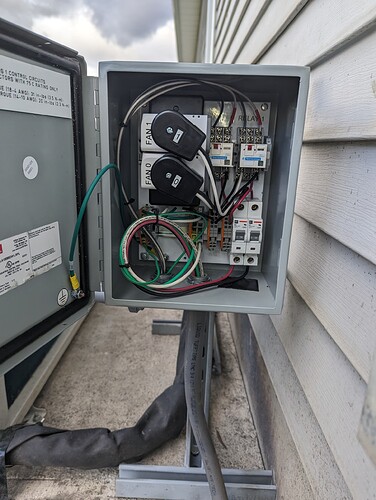

New Drycooler fan control box. This is basically a relay for each fan so I can have the fans off, one on or both on. This can all be controlled in node-red.

Overview/Design of the reclamation system:

the only picture missing is the actual immersion system you are using and the miners , thanks for sharing

Hey mate any updates, all running smoothly?

Everything is running absolutely perfectly! The cool season just kicked off and I activated the reclamation system again and it’s a beautiful thing to be using all that heat. I refined the thermostat setup to use the Ecobee Premium so I can control it through node-red and I’m able to have it maintain a specific heat range automatically. It’s working exactly as a normal furnace would except with miner heat. It’s basically completely hands off.

The only aspect really that I’ll adjust is the maximum temp I will allow the miner oil to get. As the temps get colder I will let this get to a hotter temp so that I can get a hotter water temp for more heat for the house.

The fan controller worked flawlessly over the entire summer. There wasn’t a single issue. I’m sure it saved me some $$ not running the fans when necessary and also maintaining the most efficient miner temps.

My water pump is leaking, but I do have another. It’s just a mess to swap them out and I’m trying to think of some tweaks I want to make while I have the water drained out of that part of the system. I’ll hopefully get it replaced within the next couple weeks. The automatic water glycol makeup system is a godsend here. It keeps the system full and I can just top it off a little here and there as I lose water through a failing pump seal.

If you have any questions, let me know! I didn’t get notices/emails for your replies. I just happened to want to get on to give drew/vosk some solar advice. I’ve been trying to reach out without success. Building and designing my own solar system I have a lot to share that isn’t appropriate for a youtube comment. lol @VoskCoin I’ll create a thread for you. It’s the only way I know you’ll likely read it.

Edit: A couple additions.

I hope to keep the S19XP units running until next halving. With solar and heat reclamation they are still pretty profitable right now. I expect them to be profitable through 2025 and hopefully 2026 running 24/7, mostly due to price appreciation of BTC. My plan would be to get a new immersion tank and immersion specific/designed machines after next halving. In 2027 and 2028 I would likely shut down the miners in the warm months and turn them on in the fall through spring for heat and to utilize my banked power from solar.

A design change I will likely make too is to directly cool the immersion fluid through the dry cooler. This would be a lot more efficient because I wouldn’t have to run the water pump during the summer. It draws about 4-5A at 240v. That’s roughly 1000W wasted 24/7 during the summer months. I would also be able to cool the miners more efficiently since the oil would be directly cooled. My only hesitation is when the need for repair arises, the oil is a ***** mess and you will lose a bit if you need to disconnect hoses. That could stop me from doing that, but I’m not sure yet.

When I get new miners I will heavily look at data regarding efficiency of the miners at higher temperatures. I would love to run the oil output temps at 50-60C safely and not kill efficiency.

I have mostly decided it is a waste to warm domestic hot water due to the cost of the components to set it up. It’d take way too long to recoup the cost. If I got a hot tub then I may heat that and setup a storage tank to heat the house water too. It’s just too small of a quantity. You would need a larger scale need for hot water to make it worth it and a single house isn’t unless you can get parts super cheap, which I haven’t been able to find the storage tank for cheap enough. Also, the temp of the miners I would need to make the water decent will decrease the efficiency of the miners beyond the gain of heating water. I just haven’t been able to make sense of this adventure yet.

One last edit:

I am looking to get a spill containment pallet for the mining system. At some point there will be a hose/pipe/seal failure. I will put the immersion system on the containment pallet. This way when that time comes it will be 99% contained within the pallet. I would get a 2 drum that holds about 66 gallons. They are about 15" tall or so.

That’s brilliant mate, I’m thinking of making a sand battery for my water cooled miners and running copper pipe through the sand and then using the heat in winter, and then hooking that up to a heat exchanger for underfloor heating. I have no idea how well it will work, but I have spare 1000L shuttles I can fill with worked dirt from my farm so I’m keen to give it a go