Rough man. Heal up!

doing my best. S*** happens. gonna run into town to get a bunch of electrical stuff today. that way if I’m feeling decent this weekend then I can do some wiring.

I managed to get into “town” yesterday and got almost all of the electrical stuff I will need. We have a great salvage place here that is usually my first stop when I have a decent list of stuff. Most of the things there are actually brand new old stock.

The immersion fluid will be here tomorrow. I got this from Ryan Hawkings. It is “TerraCool”. I’m definitely still a bit nervous throwing these machines into anything. I mostly say this because they aren’t directly or initially designed for this.

Immersion fluid is here! Now I just need to get my butt in gear to finish up the electrical and plumbing.

I’ve been busy working on electrical and making good progress. I changed out the wiring and did “seal tight” to the dry cooler with #10 mostly to protect for the 20A 240v circuit.

I added a 20A 240v circuit where the water pump will go inside as well. At least close to it. A couple breakers were changed/added.

I’m waiting on some 1" “seal tight” to show up. Hopefully it will be here by the end of this week. I found a good deal on some new old stock on ebay that was 1/3 the price of local. For about the same price as 20ft locally I got 70ft. I didn’t necessarily save $$ here, but I got a lot more for any future needs.

edit: the hand is doing much better and healing freakishly fast. I’m not complaining.

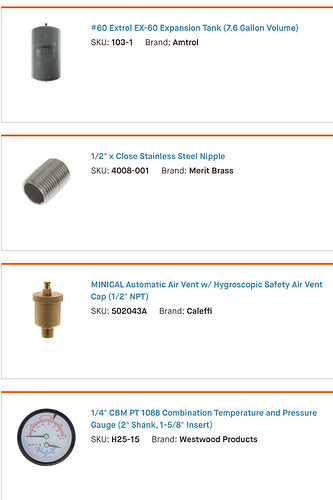

Not much too report other than I’ve been thinking a lot of the water side plumbing. I finally ordered up some parts after figuring out mostly how I want to do it. There are still a couple aspects that will be up for “debate”. Stainless components are the cheapest. I wanted to keep as much of it as possible stainless and copper due to “galvanic reaction” within a system due to dissimilar metals.

The expansion tank should be used because as the water heats up in a closed loop (not open to air like the oil side) the water expands and needs somewhere to go. This is where the expansion tank comes in. It has a bladder in it that is pressurized and allows water to push up into the tank. I didn’t bother with figuring the size of the tank. Most systems I see for residential boilers use a smaller tank, so I just got a little bit larger to make sure there is enough capacity. It’s the better way to go on the scale.

I also wanted to be able to monitor the inlet and outlet temperatures so I got some combination gauges that will give pressure and temperatures.

Lastly, the air vent will help remove bits of air in the system after the initial purge and from heating the water.

These is also a larger air vent unit called an air scoop or air separator, but I’m not going to bother with that right now at this point in the system. I am at the place in the project where I need to get this thing up and running and these components will do just that.

I was not familiar with “thread cord”, pipe thread sealant. Loctite 55 is the stuff to get, apparently. Some of the fittings that are BSP (11 TPI and tapered) bottom out before getting snug. The thread cord should remedy this from what I’ve read. I have high hopes for this and it would definitely save me time and make me feel better about the connections on the water side.

As always, feel free to shout out if anyone has input or questions.

DO NOT PUT COPPER AND STAINLESS NEXT TO EACH OTHER!!! It will not last

Can use some brass copper is not good at all with stainless

At current, I don’t think there is anything in direct contact. The heat exchanger has stainless fittings and most of the rest of the fittings I have are stainless. The air cooler is a copper tube heat exchanger/cooler, which is recommended for “boiler setups” as opposed to aluminum due to its reaction with other metals. I think the brass components are the air vent and gauges. The gauges have a copper probe.

Yea shouldn’t d be problem but normally if u go stainless it everything stainless or copper same thing copper will degrade by 50% or more when in close contact with stainless

Thanks! I’ll be sure to keep that in mind with the stainless and copper. I continued with stainless fittings for the simple fact that the system came with stainless fittings as to keep things as uniform as possible. Granted it’s not going to be possible to get everything in stainless.

Then I’d try brass over copper or even some type of high temp plastic fittings. Also know that new copper pipes and fittings will leach copper into any solution u are using. After awhile it will build up a coating but new will put copper into your solution. Not sure if that matter but another thing to know

Also keep going man it’s been awhile since someone has brought some useful shit here this and your pool shit has been great

Thanks! I’m a big fan of forums. Chat is great, but it’s hard to reference back to things and there’s no real good way to bring that content to search engines for others to find. I’ve been watching Vosk’s videos since he started and he seems like a good guy, so I like helping out.

Slowly getting there. 100A of electrical is finished up and the immersion tank has power to it. I’m waiting on some fittings from the seller of the immersion tank. He was kind enough to send me some fittings for the 1.5" hose. This was a great help.

All of the plumbing is “routed”, however I still need to clamp and finalize it and hang the expansion tank. SupplyHouse was out of the mount kits, so not sure what I’ll end up doing to mount that nicely. I’ve been too tired to care or think of a solution there.

I ended up getting some t-bolt clamps for all of the hose connections vs the screw style clamps. I just like them better, but they don’t have a large working range so you have to be careful when buying.

I was able to test the oil pump real quick and it works. The temp probe was set to 14C and it was reading 24C, so it tripped the contactor. It’s good to know that works well. It appears I can adjust that temperature up to 59C.

As far as I know, the rest of the parts will be here this week. At this point just clamps and fittings.

Once I finish that up then I’ll go ahead and start running some water through it under pressure to see if there are any leaks and address that. For now it will be 100% water. In the fall I will do a glycol or similar additive to prevent from freezing, in the event I can’t run them for some reason (power outage or broken components on the immersion system).

It’s getting there. I just need to get some distilled water for a test on the water side to check for leaks. I’ll need to get some hose and fittings for the pump i’ll use to fill it as well. I think that’s about it. Here’s to hoping for no leaks. I’ll tidy up the hoses a little and I may try and order another 90* fitting to come off the heat exchanger. It would make the hoses a little tidier. I may do that when I add in the glycol/propylene.

This is what I’ll get, I think.

https://www.supplyhouse.com/Hercules-35285-Cryo-tekTM-AG-Anti-Freeze-Glycol-5-Gallon

I’ve filled the water side and had a couple leaks at the connections that go into the pump itself. I changed the type of thread sealant and used a couple types. One has an anaerobic cure time of 72 hours, so I’ll need to wait until Tuesday night to try filling it again. Everything went well and the main water pump turned on without issue.

I’ve just been putting together another order for hopefully the last batch of parts and I would like to add a water makeup system. I am looking at the GMP4, which will add water when the pressure drops below the set level in the system. If I have the expansion tank set to 20lbs and the makeup system set to 18 or so then it’ll add up to 18. I don’t think you would want to be more than the expansion tank because it would just want to fill it and that would defeat the purpose. Granted, the expansion tank pressure would increase as it filled. It is currently set at about 20lbs (depending on what gauge you read, lol). This way I can keep tabs on the water level in the system. It will have a 4 gallon capacity and you can put the glycol mix directly in it.

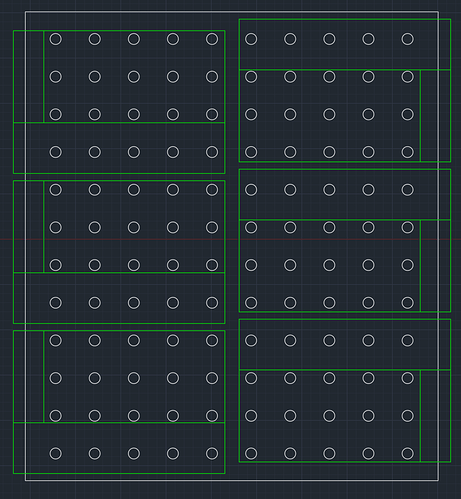

Something I hadn’t looked at until today is the ideal configuration of the miners based on the flow plate design. I took some measurements and made this up in autocad. The dimension should be quite accurate and close enough for the purposes. I will only have 4 units. I will probably put one in each corner to as to be sure it keeps the flow plate pinned down well so fluid doesn’t bypass it. I’ll probably put a block of plate in the middle so that fluid is encouraged to go through the 4 miners instead of the open holes (least resistance).

I ended up getting cryotek 100 and will go with a dilution that will provide protection between 0-10F. Really this is only an issue if the system isn’t running at all. Even with just the pump running and no miners you would not have issues down to colder temps. The higher concentration of propylene glycol (PG) that you have the worse the heat transfer is. You want to try and use the least amount as possible, however I have seen that having 30% plus with the additives is recommend at the minimum to help fight against corrosion, scaling, and bacteria. I’ll be shooting for a 40-50% with respect to cryotek-100. This could be different with a different PG as they may be a different “dilution” in the way they come.

I’m running out to get a different transfer pump and a couple hoses for the immersion fluid from Ryan Hawkins (TerraCool). I want to initially pump some fluid into the unit overflow and run the pump to circulate some fluid and then let it sit there for a day to see if there are any leaks on that side of things. I’m really hoping not as I didn’t have to assemble anything on this side and that would likely set me back and it is suppose to jump in temps this weekend quite a bit.

We are currently at about 60F give or take and Sunday it is supposed to be 91F last I checked. I would like to get some miners in the system before then. Ideally, I wanted to test a single miner for a week or two, but that’s not going to happen with the unusually high temp swings at this time of year.

The PG will be here Thursday, so I’ll be able to do a final fill and leak test Thursday or Friday and hopefully clean at least one machine Friday or Saturday and immerse and see what happens.

I don’t want to miss out on any noticeable down time because BTC rewards are quite good right now relative to recent rewards.

In case anyone was curious if I’m nervous about immersing a bunch of expensive equipment (to me), YES!

At current, I will be using fan spoofers vs custom firmware. I have amlogic boards and it’s possible to flash them if you have someone come into your network through a VPN and do them. You still have to pay a dev fee even with stock settings, so as long as the fan spoofers work well then I don’t see a need for it at the moment.

Hey you probably know this but be extremely good at clean the asic out break them down completely even if new

I wouldn’t be worried about putting them in. My worry would be breaking them down cleaning them good and putting them back together