Thanks! Yes, I will be breaking them down and cleaning them. I have some 90% isopropyl and some terraclean from Ryan. Any tips on cleaning? @Smokey024

Lol nope goes against my morals if it’s not broken dont take apart

The oil side is filled up with a full 55 gallons. I may have to put more than one machine in at first just to get the oil level up. It is just a tad low and I don’t have any more oil. I’ll probably end up ordering more (ugh $$$) just to have some on hand in the event that there is a leak or a part needs replaced on the system and I lose some. This way I will have enough to get going again. I suppose if I have more then I could make a smaller system and add more miners ![]() (jk, probably won’t add more miners). The most I would add is two more for the 6 unit tank.

(jk, probably won’t add more miners). The most I would add is two more for the 6 unit tank.

I do think that it is possible we could see more mining units like the ms6+ (I think that’s it). The whatsminer immersion specific unit. I think it sits around 25-26th/s, which IMO isn’t that great when you then factor in the energy to cool it as well. I think the S19XP units will still be around that 21-22Th/s consumption with the fans removed and then adding the pumps etc… back in. Adding in two more units would increase that efficiency as well as it won’t cost me any more power to cool them.

On a note, I see the XP units take anywhere between 11.75-12.00A at 240V (at the pdu) when they are fed sufficiently cool air. I expect that completely removing the fans would likely have them sit around 11.5-11.75 at the least. When they get hot due to rising ambient temperatures they will pull as much as 13.0-13.35A.

The glycol will be here today, so I’ll be able to get that added into the system and pressurized again to check for leaks. I will probably run that pump for at 12-24 hours straight to make sure there are no issues with leaks or the pump. Assuming I can get that done tonight, I will probably get a unit (or two) dunked Friday or Saturday.

I still need to run a network cable and check the little switch it came with for full functionality/connectivity. Luckily, last summer I ran ethernet into the garage in a few locations. One of those locations being right above the immersion system (luck). That will be as easy as making a cable up and routing it down the wall nicely.

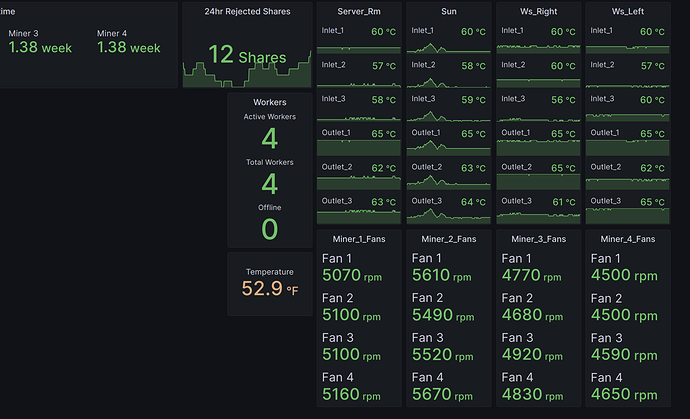

I log data from the miners. This is just a preliminary dash that I’ve created. I’ll need to go in and grab the temp of the chips as well so I can check them. I think when I was making the dash I ran out of time and didn’t add that data.

glycol showed up today. I have it added to about a 40% mix with the cryo-tek 100, which will provide plenty of a buffer if the system goes down during a really cold period in the winter. Worst case scenario (Armageddon status), I can drain the system. This will protect me on burst temperature to somewhere around -10F.

The system is holding pressure with zero leaks. I ended up using loctite 55 thread sealing cord on everything except the pump connection to barb hose fitting which I used loctite 55 AND loctite 592 (could also use 577, which I didn’t have). I ordered some 577, however I had only 592 here at the time. This combination has worked gloriously. In fact, the only leaks I had that I couldn’t remedy with a simple snug up of the fitting were those that had teflon tape.

Currently, the water pump is running and same with dry cooler. I will run them for the next 24-48 hours, depending on when I get to cleaning miners and putting them in the immersion fluid. It’s really just a test to check functionality of the components and potential leaks. If it can’t last 48 hours without issue then I surely don’t want to move forward with immersing until any issues are resolved.

I should be immersing a unit this evening. Pics to come of the setup once I get one in and get the area cleaned up a bit.

A small update. I have had a unit immersed since last friday. It seems to be performing well. I have ordered another 10 gallons of fluid from Ryan as the tank needs a little more and I’m not comfortable yet at this point immersing the rest of my investment (my other miners). If I put the other miners in there I would likely have enough fluid from displacement. Using an ampclamp, the system is drawing 13.6A at 240V with a single miner. This doesn’t account for the water pump or dry cooler fans. This is one miner and the oil pump. The oil pump is spec’d for 550w.

550/240 = 2.29A

13.6-2.29 = 11.31A (miner only consumption)

I’ll be able to get this a little more accurate when I add another miner and see the difference in consumption.

Granted I am using more power with only 1 miner in there, but as soon as I get them all in there this will make me just as efficient or more than air. I am also using extra fans to keep the air cooled miners running as well which all adds to decreased efficiency. The big question that is eating away at me is if the machines will stand the test of time in the immersion tank. There is the tank design and miner design as well. There have been issues with the XP units failing (air or immersion) due to the aluminum pcbs (most likely).

Hey mate how’s it all coming along?

I just have a quick question - with your tank, will the system run simply by turning on power points or do you manually have to turn it on with buttons or anything by hand?

I’m debating getting one, and would only want it to start by power point because I can start it automatically with wi-fi powerpoints which have scheduled timers

Thanks mate!

There is a contactor that can be tripped (oil temp sensor is hooked to it). I bet that you can work a remote on/off for that contactor so you can do what you’d like. I’m not sure how as I haven’t gotten far enough to dig into this. Give me another few weeks to provide a better review prior to making any decisions unless you’re needing to get some sooner.

I will be providing more information regarding the unit from a review perspective in 2-3 weeks (dependent on when I get more units immersed, ambient temps, etc…).

I will say that I do really like this unit for the fact that it has a large tank that can be utilized for pretty much any asic machine now or in the future. This was one of the driving factors for getting this unit. The flow plate can also be replaced for something more specific to needs where so many others didn’t allow this.

Feel free to reach our directly or through this thread and ask any questions you’d like.

Hey, Hows the immersion project going? Have you added your second miner yet?

It’s going well as far as I can tell. I mean it is one of those things, I think, that it will go well until it doesn’t. I will provide a decent update later today or more likely tomorrow.

How many do u have running now

2 are in there right now

A small update prior to a larger one. I ended up doing yard games all day yesterday with friends and family on the day off.

Seemingly, everything seems to be working properly. I do have the machine that is in there hashing at about 133.5 Th/s and the typical for all of these machines is 135.5 (based on what I’ve seen in the last few months running them in air). The other machine I just put in is hashing at 135.5. I’m not sure. The hardware errors seem to be about the same so far as in air. I keep a close eye on these metrics as so hopefully find possible issues that could be cropping up. I would say that the 133.5 (OG xp dunked) has slightly more errors, but it seemed to get some on startup.

One thing I will say by looking at the logs is it wants the pcb/board temps to be 35C and when it doesnt hit 35C it seems to just proceed anyways. This is interesting.

I haven’t seen anything concerning or abnormal otherwise in the logs that would suggest any kind of issues. I think this Friday will be 3 weeks on the original machine in the tank.

There is thermal paste on the top of the flow plate. Pretty much everyone I’ve talked to says this is normal, expected, not an issue, etc…

I want to test this next thing before making any definitive conclusions, however I believe the installation video for this unit has them hooking up the heat exchanger, relative to the dry cooler, backwards. If you lf you look up information regarding heat exchangers and specifically brazed plate heat exchangers then you will find that you can hook them up in a more ideal flow direction. If the fluid flow in the same direction then that is called parallel and in the opposite direction would be counterflow. You want counter flow because the opposing speed and larger temp difference pulls more heat off and thus providing a better “cooling effect”.

As far as I can tell they have this thing setup in a parallel flow. If I had the datasheet for the brazed plate heat exchanger then it would really help. There are single pass and dual pass (multpass) brazed plate exchangers (similar to radiators). I am assuming this is a single pass, which would make it hooked up backwards. It most definitely still cools, but there should be a decent difference between the two directions. This will become more important as I add more miners.

Currently when it is about 75-80F outside the outlet temp of the oil is about 32-34C and the outlet temps of the miners sit at about 60-61C. Still all within a completely acceptable range. My concern is with the flow plate design is uneven flow through the miners and hotspots. there is way more than enough flow with the oil pump. The flow is roughly 36GPM which leaves 6GPM per miner (if filled w 6 miners), but not all of that goes to each miner because a good portion flow through other holes (least resistance and for the power supply. I did the simple math and each hole gets about .3GPM (if evenly distributed, which it won’t be). If you ideally place each miner’s set of hashboards over 15 holes you would be pushing about 4.5 GPM through each miner where it really matters. I guarantee this much isn’t actually flowing through the miners and it much less.

I see a lot of people in the immersion cooling telgram talk about roughly 2.75-3GPM per miner. It may be somewhat close to that (maybe). This is very hard to determine or estimate with this type of setup.

The electrical that was provided with the unit is doing well and not getting hot etc… The contactor and temp sensor work well. I do wish that when the temp threshold was met and it shut down the power completely that it would stay off until you manually switched it back on. IMO if that gets tripped then there is a larger issue at hand that needs addressed. Without the way it is setup it will continue to then start up, over heat, shutdown, start up, over heat, shutdown, and on and on.

I love that it has a lid, which was definitely something I wanted. It is in my garage where it gets dusty etc… Yes, you can probably add a lid to almost any tank out there. I just think of how much dust will collect on surfaces and this would all end up in the fluid otherwise if it were open. There are vent holes in the tank around it. I wish they were not there and I will probably cover them up. There is a vent/opening where the power cables pass through anyways. My reasoning for this is you can still get bugs, mice, whatever that could climb in there. I live next to farmland and that is something one has to think about.

I think a nice addition for the flow place would be to have locator tabs for the machines that could be removed/changed for different machines. It could be configured to have tabs for the most common machines (s19 and whatsminer). This way they can sit in there straight and be centered as best as possible of the flow plate holes. A distribution pipe under the flow plate would probably help a LOT with a more even distribution of the flow.

I’ll provide some pics later and more details as well. I just wanted to get something out there for those that wanted more information.

edit: I think I will feel comfortable with the long term stability/reliability of these exact machines in immersion and the setup if they are still chugging away somewhere between 3-6 months. Not sure exactly when I will feel completely good about it, but I imagine within that time frame.

I am waiting as long as possible to submerse my other two xp units (only other units I have).

If anyone has questions or wants to me check something, get a pic of something on the unit etc… then just ask away and I would be happy to.

I’ll have some data coming in the form of graphs. IMO it is suggesting the units are not getting appropriately cooled (evenly) when the temps get in the mid 70s and up outside (F). There are only two miners in the tank. Temps on the miners themselves show OK, but the drop in hash coincides each day with the increase in temperatures outside, which lends me to believe this the issue. output temps on the oil are ONLY 34C which is way cool. The miners should be basically cold through and through.

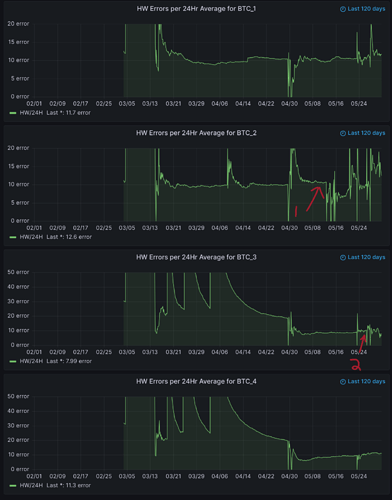

I realized I had been logging hardware errors, hash, and some other useful data all along and just forgot I was writing those datapoints to my db. Data bomb inbound soon.

If you don’t mind me asking what did it cost you to this point. Was hoping to see huge improvement but doesn’t seem. I might be reading some of the stuff wrong. I still think it’s cool

It’s not that immersion isn’t great, IMO it is more or less the flow plate/design. Remember, this is all specifically for this immersion unit I got. IIRC the immersion system was about $5k, 2.5k fluids and cleaner, probably another 500 in parts. So about $8k for the immersion setup.

Also, take into consideration, XP units and I believe the new s19jpro+ are picky as hell. I think this is due to the single heatsink design and aluminum backed pcb vs the older fiberglass (I think that’s what they were). I think if you had older style setups there would 100% be no issues as they seem to handle heat better.

Oh no I get not cost effective for me but was definitely interested in what it cost and I trust u to a point to give me decent answers.

-

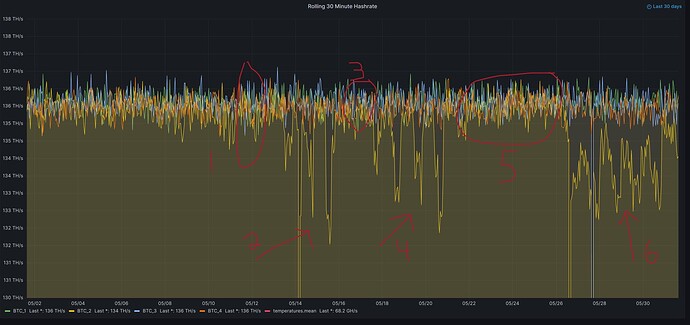

This is when I first immersed the unit. It was cooler and there is no issue at all. Seems to be running perfectly. By cooler, I mean below 70F outside. My dry cooler is also on the N. side of the house and gets virtually zero sun.

-

Points to these drops in hash on the original immersed xp. These coincide perfectly each day with when the temps get to about 75F and above and then the hash returns as it cools down. Now, we are not talking about a lot of hash, but you can compare this to air cooled machines that basically have NO deviation and they were showing output temps of 75-79C during the peak of the day at this time. I have never seen the immersion units show more than 62-63C. Seemingly there shouldn’t be a problem looking at this, but there is clearly something going on.

-

This is where the ambient temps are back down to sub 75F during the day as highs.

-

More warm weather. The same as number 2.

-

Back to cooler ambient temps.

-

I flipped the miner to have the coolant flow in the same way as the air would flow. It started off really good (at the tail end of the 5 location) and then I rebooted and now it was back to “large deviations”. No idea really what is going on here because the ambient temps weren’t that bad.

At the very end (last night) I adjusted the flow through the heat exchanger to go the other way and I flipped the miner to have the power plugs facing up.

Note: I immersed the second unit (blue) just at the tail end of the 5 circle. So far its hash has had zero issues.

More data to come…

@dirtyrandy I’ll give you a 100% honest and unbiased answer. I have absolutely no skin in the game here. I don’t make any of this nor do I earn any kind of commission whatsover. I’d be biting my nails if I was the supplier of an immersion system and someone like me was going to analyze it. I don’t f*** around.

BTC_2 is the first immersed unit on the 12th.

-

Time of first immersion

-

Time of first immersion for BTC_3, the 26th

I’m not sure what the data did on btc_3 and 4 early on. These two were on a 10kw UPS. It could just be the way the program is processing the time. It’s not really worth digging into as I don’t have the time and it doesn’t really make a difference. You get the general idea on the amount of errors/day in air and in this immersion system. It hasn’t helped from what I can see. Ignore the large drops, that is just when it restarts and there hasn’t been enough data to provide anything valuable.