I was hoping to have a different type of update aside from this, but I found I was collecting all this data today and started to dig into it for my own knowledge on it. Depending on how things go over the next week, I may end up make a new flow plate and also a sub plate flow system out of cpvc to help distribute flow better. Very frustrating if that ends up being the case.

Even if you did not receive a performance boost on your one or two units (From what I can see). The stabilization alone in miner temps has got to be worth it. Temperature fluctuation is one of the two leading causes of hardware failures.

I would be interested to see what the performance buffs to efficiency you receive at full capacity. What the system was designed for.

Only two units are submersed and that stability on one is decreased a lot. Two are air and are as stable as can be. Temps that are shown in the dash are not necessarily indicative of what’s really going on at a chip by chip basis. All of them hashed for months at basically 135.5Th/s while in air. So… The experience up to this point has been frustrating and could soon become costly.

I am a pretty patient and understanding person, but this system is really beginning to test that.

Looks like I’ll be replacing the hose before too long with something more appropriate. I’m hoping that can wait until I determine the future of this system and immersion as a whole for the miners.

Stick with it man! One of my favorite threads on here.

I’m here till demise or success! lol

I’m with badger keep it up I look forward to your post

Looking forward to the story updates

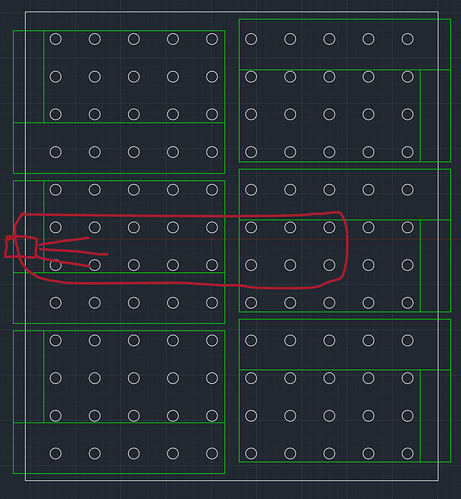

I’ve attached a couple pics that I have in the thread already, but they serve a new relevancy. I got to thinking. With ALL of the fluid flowing quickly out of one port in the middle there was a good chance without sufficient pressure that it would actually create a venturi type of effect right above that strong flow rate and thus pulling DOWN fluid instead of pushing it up through the holes in this section.

I did a very scientific test to check some flows throughout the flow plate. I tore a little piece of plastic kitchen garbage off and made sure it had a about 3-4" of a very thin stringy section so it would react to fluid flow easily. I took this and held it on top of the flow plate in just about everywhere. Surprising the some of the best flow is all the way in the back and the sides even got decent flow as well.

Guess what happened right in the middle two rows directly above the strong flow. The tail was either flat/motionless or it was pulled down under the flow plate. YES, that is RIGHT! Where you would think the miner(s) would get the best flow is actually the absolute worst. Surprisingly I moved one of the miners off this section and errors were less as the temps got warmer today. hmm… This is all despite the fact that the board/chip temps on the miner were WELL within reason (55C or so).

I only have 4 miners so it is easy enough to keep them out of the “kill zone”. I even have some stainless and may simply block this off all together.

Man it never ends, I thought immersion cooling would be so simple with plug and play. Thank you for sharing, I am still considering immersion cooling but this is a good eye opener

@ShredZ It should be WAY more plug and play when buying a system like this. I am a very busy person and I bought a system like this so that I wouldn’t have to mess with anything other than setting it up. Now I’m wasting my time fixing this system. It costs too much $$ to get a new one and I do believe I can fix this one to work properly, at least at this juncture. That may change, we will see as more data comes in and ambient temps increase.

edit: I think at this juncture I would keep a close eye on foghashing and octominer for a system. If I can get this one fixed up properly then great because it still would allow for versatility as time goes on (assuming pumps and components last). This was one of the driving factors when choosing this system. I think that other companies will allow for different flow plates down the line, but the market is still early for us small scale people.

Hey maybe I can help little what hose is that. I might be able to have u look in total different directions for that hose so it last years over weeks. Is it high temp with pressure @live4soccer7

@dirtyrandy It’s 1.5" hose and the temps aren’t terribly high with really a theoretical max of 70C (miners will be toast at that point) and I’m only running a pressure of about 20psi in the closed loop with that hose. Thanks for taking a look!

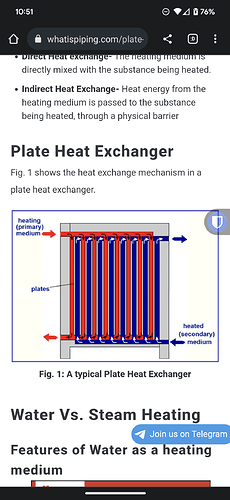

On a different note. This is somewhat the type of distribution system I’m looking at. Not identical, but you get the idea:

that is a “bixbit cell”. Something like that allow the actual distribution to be pressurized slightly which will make for even distribution to areas under the flow plate which would then even out the flow even more as it passes through the flow plate.

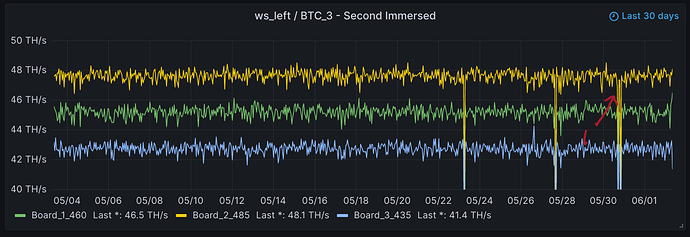

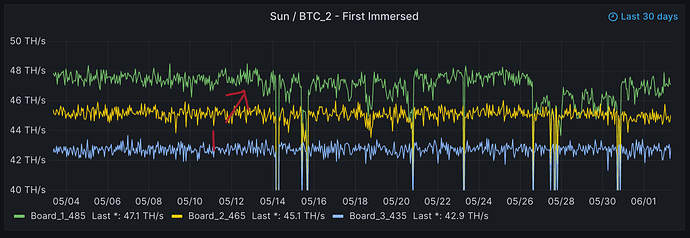

I wanted to check hash on the individual boards to see which one is under performing since immersing. You can see hasboard 1 has not performed quite right since immersing on the first unit. This miner was placed in the “kill zone”, originally thinking it would get great flow there. Pretty much immediately you can see the hash was affected.

The second miner has not seen such issues and it was never placed in this zone.

The First one was placed in the tank on the 12th and the second was the 25th. The second has been in the tank much longer without any issues at all whereas the first one started having issues pretty much immediately. I have no explanation for this other than it being in the “kill zone”. You can see the hash all the way up to immersion and it was perfect, just as the other miners I have.

any extremely harsh drops in hash, is where the miner was turned off and there is no data there.

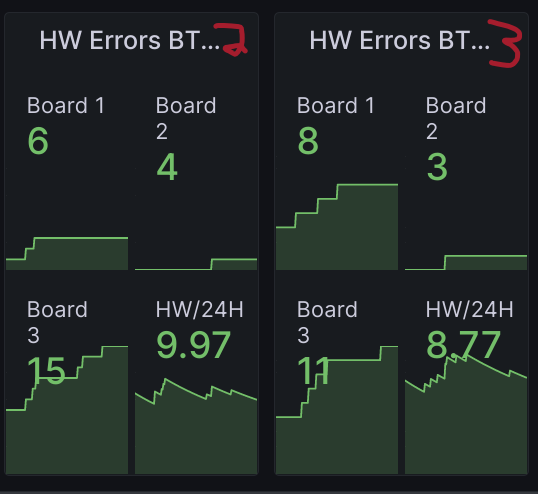

Given that the first immersed miner doesn’t have excessive errors, I’m not sure what would be causing this. In fact, that board has less errors. The 435 boards have the most on every miner.

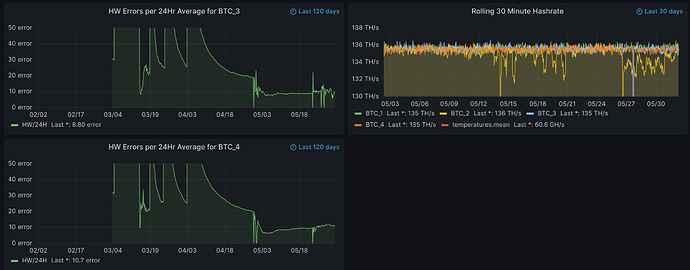

HW errors for the last 2.5 days on the immersed units

edit, in comparison the air cooled miners are currently sitting at 11.2 and 10.6 errors per day

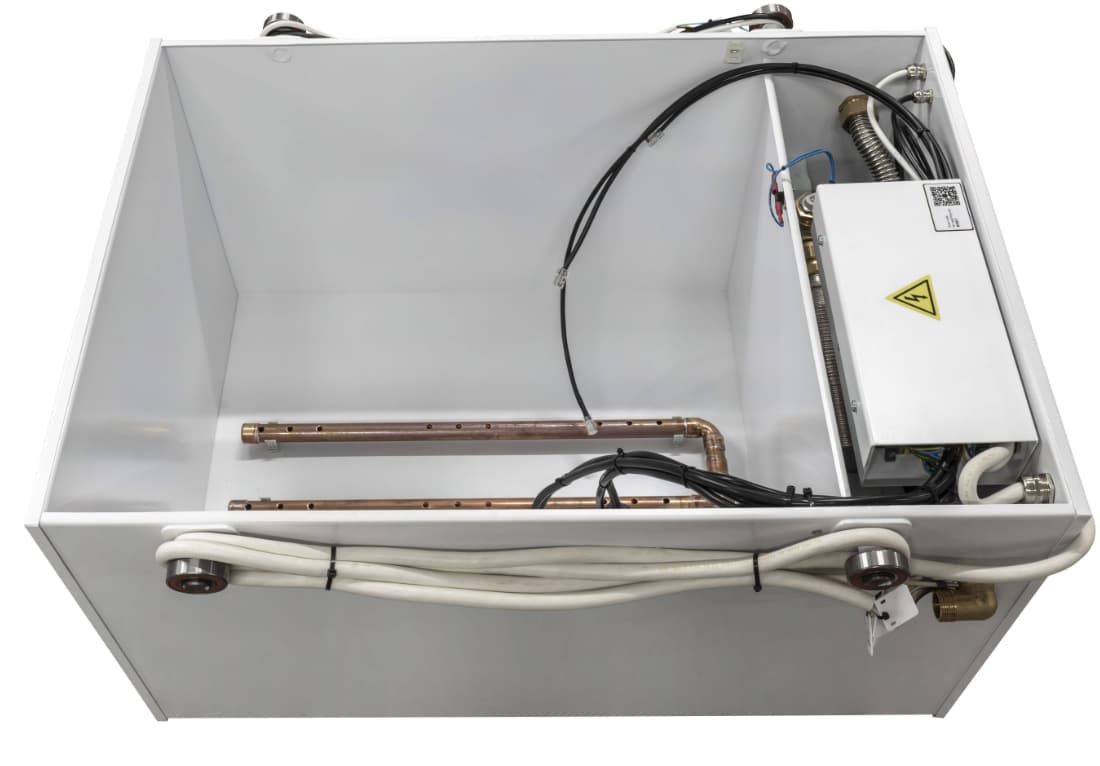

Here is a photo of how I have the heat exchanger plumbed. The left side is is the water/glycol side and the right is oil. In the installation directions/video the water was hooked up the opposite way, which is suggested of parallel flow instead of counter flow.

Suggestive by this diagram, it would illustrate the flow of the exchanger.

Well here you go thinking out of the box that size of pipe try and see if u can get a radiator pipe from a car or truck in length you need it can take pressure and heat and they will last years. You will probably have to do little research and maybe order from a dealership but they have been around for year

It’s definitely a good idea. I’ve seen some rubber hose that has a red or maybe yellow stripe on it used in other systems. I’ll see if I can also dig that info up and ask those individuals.

Ideally if this works I’ll be reworking a lot of the plumbing for heat reclamation anyways, so I’m hoping that this existing hose will simply last through the summer.

It probably will. The way it looks it might have some metal in middle of rubber like a sandwich. It looks like dry rot from sun exposure and if I’m not mistaken you are Australia so sun is strong