I’m in the US and it sits in the shade and hasn’t even been hot here. Yes, it still gets UV exposure in the shade, but that is a bit ridiculous at 3 weeks IMO. No metal.

Yea definitely not that quick yea that’s interesting wish was home to stop by classic Porsche shop see what they have to help u out. if gets worse let me know I’ll try and see what I can but I’m not home for 6 week’s little less

I appreciate it! So, I think I might be on the hunt or just make some, but don’t really want to buy a sheet of AL for this, the “grill” that goes on the output side. This is where the fans would screw to. I would like to retain the support for the hashboards in this piece, but then basically remove the grill structure and the corners. The corners block all flow. I haven’t come across anyone doing this.

edit: anyone know if there are additional logs that can be pulled off the S19 units that will show me individual ship voltages?

Minor update only. The second immersed miner is still hashing away at prior hash level (it’s doing very well). It has been in for a week and a half roughly. The first miner exhibited a decrease in hash that fluctuates with temperature just 2-3 days after being in the tank. Again, I think this is because it was in what I have deemed the “Kill Zone” inside the tank. With that said, the second miner has not had any issues beyond this and has been consistent within those confines without any increase in hw errors or crc errors (in the logs).

I am looking at options for third party firmware and xilink control boards (I have amlogic boards). I absolutely hate paying a dev fee for already super tight profit margins.

The two immersed units had less hw errors over a 5 day period than the air cooled units. Indicative of possibly higher thermal stability.

I did update the fw on the unit that has the slight hash issue (we are talking less than 2%). This did not fix the issue. I figured it was an easy option to try.

It was about 83F yesterday and the max outlet oil temp was 34C with max chip temp being 63C on one board with most being a max of 60-61C. We should get to roughly 88F in the next day or so. I anticipate putting another miner in the tank this Sunday after I see how the setup handles the two miners with the warmer ambient temps.

Another small update. It was 90F here yesterday and the outlet oil temp got to about 38C and the highest chip temp I saw was 66C, however take that with a grain of salt since the chip temps are some sort of average.

I am working on a flow distribution system. I am looking at two different styles right now and have mocked up simple designs here to test flow with water and a garden hose and then putting the flow piece in a “kiddy pool” to see how it looks and feels.

The first is basically a tube that would go under each miner parallel to the middle hash board. There would be 3 sets of holes in the tube. One right down the center for the middle hash board and then a set of holes on either side that would direct fluid to the outer hashboards. Now, this is the simplest setup, but it certainly is flawed due to the control of the fluid and how it is delivered to each board. With that said, it would be 1000% times better than what is in place now.

The second, which I will test today is a low profile box for each miner and there would be an inlet on each box that would receive flow from the main trunk line coming into the tank. Each miner would have a “Box” it sits on (ideally a couple inches above) and there would be a pattern of holes where the fluid flows through. This design is more involved for sure and will definitely take much more effort to create.

Both setups will require a different “flow plate” to set the miners on. IMO you want the miners an 1-3 inches above the actual flow so that it spreads out and covers the whole heat sink.

The hole sizes and quantities are being chosen very carefully. The issue with the current flow design and possible many (IMO) is that there is not enough restriction in the flow design. If there is no pressure at all in the distribution system then you will get uneven flow because it will simply go wherever there is least resistance or where the pressure is allowed to build up a little. In the tank/flow design of my setup from the factory this is very evident. The flow really comes through the edges of the plate.

Basically, the pump that came with the system runs at about 36GPM. That’s about 6GPM per miner. I have taken the area of 1.5" pipe (1.77) and then divided that by 6 which is .295. This is the allowed area that I am allotting for the holes. Now this is not 100% accurate because you’ll more flow resistance on smaller holes/openins due to increased surface area contact, but I think for this use it will be plenty sufficient. I think close will count as long as there is a little pressure in the distribution system then it will perform well.

I would really like to do the box setup because then I can make it so the top plate is actually removable for adapting to different types of machines. Simply make a new flow plate for the box and then plop the plate in and the different miner. If you had a larger miner like maybe the m56+ (?? whatsminer immersion model) then you could simply take up two spots or create a single larger box that would utilize two positions.

My train of thought on this system the entire time was that it was simple and adaptable. Unfortunately, I am having to adapt right out of the box. I really don’t have time for this ****, but I also have to make this work properly.

The hose cracking continues to get worse outside (expected). In the garage where there is essentially no light there are no issues. I have decided to get a wrap of sorts for it. I settled on this. Another expense on something that shouldn’t have to happen with a pre-designed system.

This will allow me to get through the summer with this system until I decide to either fix it permanently, go with a different system altogether, or in the unfortunate event that all machines fail and the whole thing is scrapped. I severely hope that isn’t the case because I have good long term plans for mining with 2-6 machines, but losing them early on without them generating enough capital would end up probably putting an end to the project.

I know it’s not cost effective but I wonder how you would go if you had 3 X 2 unit tanks connected to a big enough dry cooler with how you were saying the kill zone sucks. I’ve seen people 3D print single unit tanks, and the tanks seem to be most of the cost, I am researching what is required and want to see if I can test it on some Goldshell X5 miners that I don’t care about and go from there. Thanks for sharing all your ups and downs with your tank we all enjoy reading it

@ShredZ I would take a look at the foghashing C1 or C2 machines honestly. I haven’t seen them in person or tried them, but they would be high on my list to look at for a smaller tank. I know that octominer has a tank and I think they are coming out with a 6 unit tank too.

I had originally looked at the octominer tanks and ALMOST pulled the trigger, but I would have to move them from inside to outside and vice versa to utilize the heat from them unless I put them all in a central location and "combined them, but it just didn’t make sense to do that.

The tanks can be expensive, but dry coolers, pumps, and heat exchangers (if you’re doing dual loop for heat reclamation) are quite expensive.

Man once I get home I’m going through the pipes I have if u give me length and size I’m gonna try help u out feel bad it went that fast and if I got one I’ll mail it out so u don’t have to keep spending money

@dirtyrandy I really appreciate it. I think this should do the trick for now. I’d be curious what you have though. The next real option that I know of so far would be to look at hydraulic line suction hoses, which are in the ballpark of $10+ a foot. I will hopefully be re-doing a lot of this when the heat reclamation phase kicks off and I’ll find a more suitable replacement. I do really like the idea of a flexible hose because it would make it soooo much easier to replace the drycooler if it ever needed replaced. I do tend to look too forward on things and I doubt it would need replaced in any reasonable amount of time. A hard pipe would probably be the best and just paint it gray.

I’m chomping at the bit to get another machine in there. The second immersed one is still doing great with the first one not showing any definitive signs of additional degradation. I should be receiving a photo of the flow distribution system on the larger asicshield systems. My guess is it is just a simple set of perforated pipes. I’ll take that with my ideas and the ones I’ve seen and come up with a game plan on what I want to do. I need to have a plan by the end of the week so I can move forward will full immersion. If it is simply perforated pipes, I may see if they are willing to just send me a setup for the 6 unit system I have simply so I don’t have to waste more of my time. I know any distribution system will be way better than what is in there.

I am still on the belief that a distribution system that is on a miner level would be the absolute best. I can usually come up with a reasonably good way to do it, but I’m drawing some blanks. I have many ideas, but the implementations are a bit more complex than what I want to spend time on at this moment.

Lol you gonna have a Porsche hose what I have tons of it’s what I normally choose to restore on my builds when I do a restoration or a eu car I love those two seater cars

They are most definitely fun cars!

Minor update.

The miners seems to be maintaining with over a month on the first one and 2-3 weeks on the second one. The second one is still hashing at full hash and the first one is still about 1-2% less than full.

I got the sleeving in yesterday and put it on today. Not the most aesthetically pleasing thing, but it should do the job to get me through until I need/want to change things up.

I should hopefully get the flow distribution design that asicshield uses on their “larger” tanks (apparently 8+). Why the heck would you not include that on the 6 unit tank.

Very nice!

I got the pic of the “distribution system” for the unit and it’s basically what I thought. It is simply a set 3 tubes with holes in them. I think that would be better if the actual flow plate had more but smaller holes in it because currently, IMO, the machines should be places just perfectly over the flow plate holes to capture the best flow over the boards.

I’m undecided on what to do at this juncture, which is fairly a-typical of me. I usually find a clear way and go for it.

I did ask if the seller would send me a distribution system for the unit and he kindly declined saying it would be cheaper and easier for me to just make it. That is beside the point. I have had to deal with many things and some of which I haven’t shared here. He is also blaming the distribution of the fluid on the fact that I don’t have it full of miners. It’s a small argument, but not a strong one. It would help marginally. There would still be very weak and strong areas of flow as putting miners on the plate will not create that much resistance to even out flow.

With 4 miners in the tank and middle section blocked off I almost think the flow may be sufficient if the miners are positioned just right. I may shut down the system and let the thermal paste settle so I can see better and do another flow check and decide. Then I can mull over if I want to design something elaborate with extremely good and even flow. I’d likely need to get out the oxy act setup and learn to weld some stainless again. Either that or just go with AL on mig. I’d probably choose whatever I thought would be the most compatible. It is hard to say given all the materials the tank is made of (steel with a stainless plate now) and then the miners are a mix AL, steel, copper and I’m sure many other metals.

Steel and stainless doesn’t mix well

No, they do not. You’ve also got to look at the screws on the miners, they are stainless that touch steel that screw into aluminum. lol

Yea never got that still don’t was trained that long time ago wasn’t to sure how true but lived by it. Truthfully it’s only long term and miner will be garbage by that time

I have found a really cool table that helps with the metal compatibilities. I’ll see if I can dig it up in my phone.

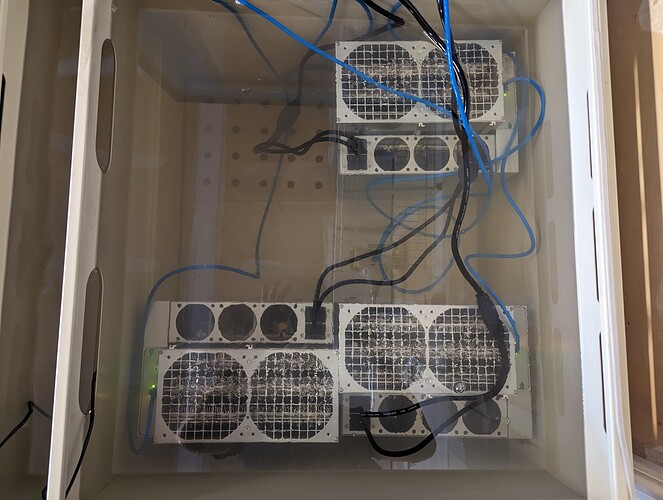

6-20-2023 we have the 3rd miner in the tank.

Top right is the first miner immersed

Bottom left is the second

bottom right is the third.

The positional and orientation has been chosen very carefully. It’s quite cool right now, so can’t say much about temps at the moment. You can see in the middle section there are no holes. That is what I have covered with stainless since the flow plate is stainless.

This sunday and Monday it will be 85-86F ambient temps. I’ll see how the miners and tank do and then I’ll be immersing the last one unless I find something I don’t like. I will say that immersion is extremely satisfactory. This is the quietest my home has been since I can remember and I’m using more power than previous ventures. Granted the longevity is there on the miners themselves, I would 100% recommend immersion, even for one or two miners. Once I put the final miner in I’ll get some power number on everything. I will probably be slightly less efficient than cool air, HOWEVER they pull a little over 13A when hot outside and you have all sorts of other fans and things going to keep air flowing. I’m quite certain that I’ll be less power. Even at 13A each I would be a little over 23W/TH (135TH). I’ll do some comps at the “end” once theyre in there.

I’d like to tidy up the cables and get my handles on too. They should be arriving soon. IF they do well in there as shown with all 4 then I’ll be content with the setup and in no hurry to make any kind of flow adjustments. I’ll be keeping heat reclamation in mind and probably start working on that mid to late august if everything is still running well and there is no indication of issues. I just don’t want to invest several thousand or so in reclamation just for them to all go to s*** a few months later. I would like to continue to mine with 4 units (maybe sometimes 5 or 6) for the long term since I have enough solar to cover 2 units on an annual basis and they would provide heat for everything and hot water to feed the hot water tank.

I think the plate in the middle helps a LOT.

Wow!!!

Firstly, thank you for sharing your experience on your immersion journey to date. I really appreciate you sharing your trials, successes, honestly and perseverance with a supposed “off the shelf” solution.

I have been researching immersion in my spare time over the last two years. I have not pulled the pin yet as I do not have the time in my busy work schedule.

I run an electrical contracting company, I have built and own a couple of run a run of river hydro electric power plant 2004 (12 kW) and 2017 (small 100 kW 24/7 365) and I have air cooled miners.

I designed and built most all of the systems myself. The intake, the penstock, the power house, the control system. I did buy a custom made Chinese Pelton wheel and a custom made Mexican made generator as I simply can not do those things myself.

There were months of tweaking and redesigns. But like you I stuck with it and I am happy with the results.

Keep going, you are on the home stretch!

I totally support your amazing journey and hope you get the flow issues sorted out.

I had a question about the dry cooler, do the fans have a temperature driven fully variable speed control by an EC motor or VFD? and if so which and are they quiet (ish)?

I am not an expert in thermodynamics and flow modelling but I had an idea, I wondered if packing the tank voids between the miners and between the miners to tank walls with an EVA foam like the jigsaw style floor exercise matts would solve this issue. Though compatibility with the coolant may be a consideration. My thought was to force the coolant to only go through the miners giving it no other choice but to flow over those hot chips. I wonder if it would reduce the seepage from the edge of the plates and help increase the pressure enough to reduce the venturi effect? Maybe it could work in conjunction with your new manifold design.

It is unfortunate that the pipes have degraded so quickly. I think the automotive stuff on the pressure lines could be great, Gates does both hydraulic and coolant ones (no affiliation - I have never had an issue with this brand so far):

Hope you find a good solution to your flowmageddon issues!

Again, thanks for your amazing posts and updates, I look forward to them!